We provide comprehensive electrical contact evaluation, custom process characterization, and root cause analysis services for defects, especially electrical interconnections, to improve the performance and reliability of your systems.

Process Diagnostics

Process Analysis

High-throughput Transport

- Re-enactment of highly accelerated transport processes (e.g. vacuum transport)

- Characterization and evaluation of process limits

- Avoidance of handling damage

Reference Projects

AluPV - aluminum facade elements with integrated photovoltaic modules for architectural solar facades

Period: January 1, 2023 - December 31, 2025

Project Objectives:

- Modular facade system consisting of PV and design elements for aesthetically pleasing and energy-generating facades.

- Production processes for the long-term stable integration of PV on aluminum components and for the construction of lightweight BIPV modules

- Fulfillment of building code and photovoltaic approval and certification tests for BIPV modules

Project Manager: Ringo Köpge - ringo.koepge@csp.fraunhofer.de

C3 Project

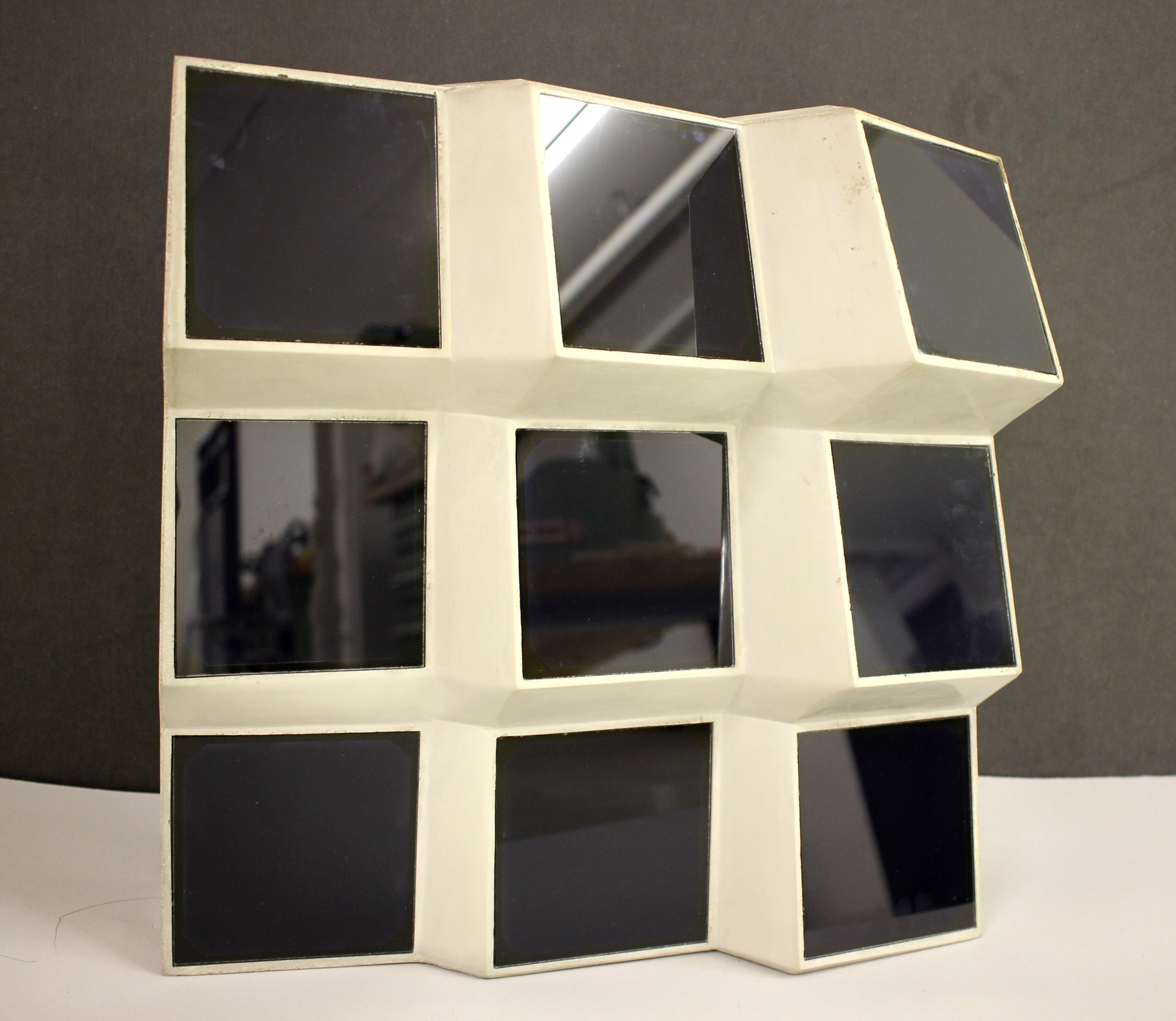

In the C3 (carbon concrete composite) project more than 150 partners from science, industry, organizations and associations are committed to promote the application of carbon cement. Instead of mantling steel with concrete, as has been done in previous constructions, carbon-fiber constructs are now supposed to be mantled with concrete.

C3 is considered to be a moldable, stable, intelligent, low-pollution, better recyclable building material and fit for the integration of renewable energies. We at the Fraunhofer CSP are one of the project partners and concerned with the question of how photovoltaic elements can be integrated into cement and electrically wired so that an optimal electricity yield will be achieved.

Of three possible methods to achieve building integration we focus our attention on casting the solar modules directly into their corresponding recesses in the cement parts, laminating or gluing them onto concrete slabs, and finally the attachment of the solar modules by means of snap buttons and screws. The latter method would make the modules removable.

It showed that the electricity yield increases when the facades are not plane. The surface that can be exploited by photovoltaics is increased either by inclination, tilting, domes or facet optics.

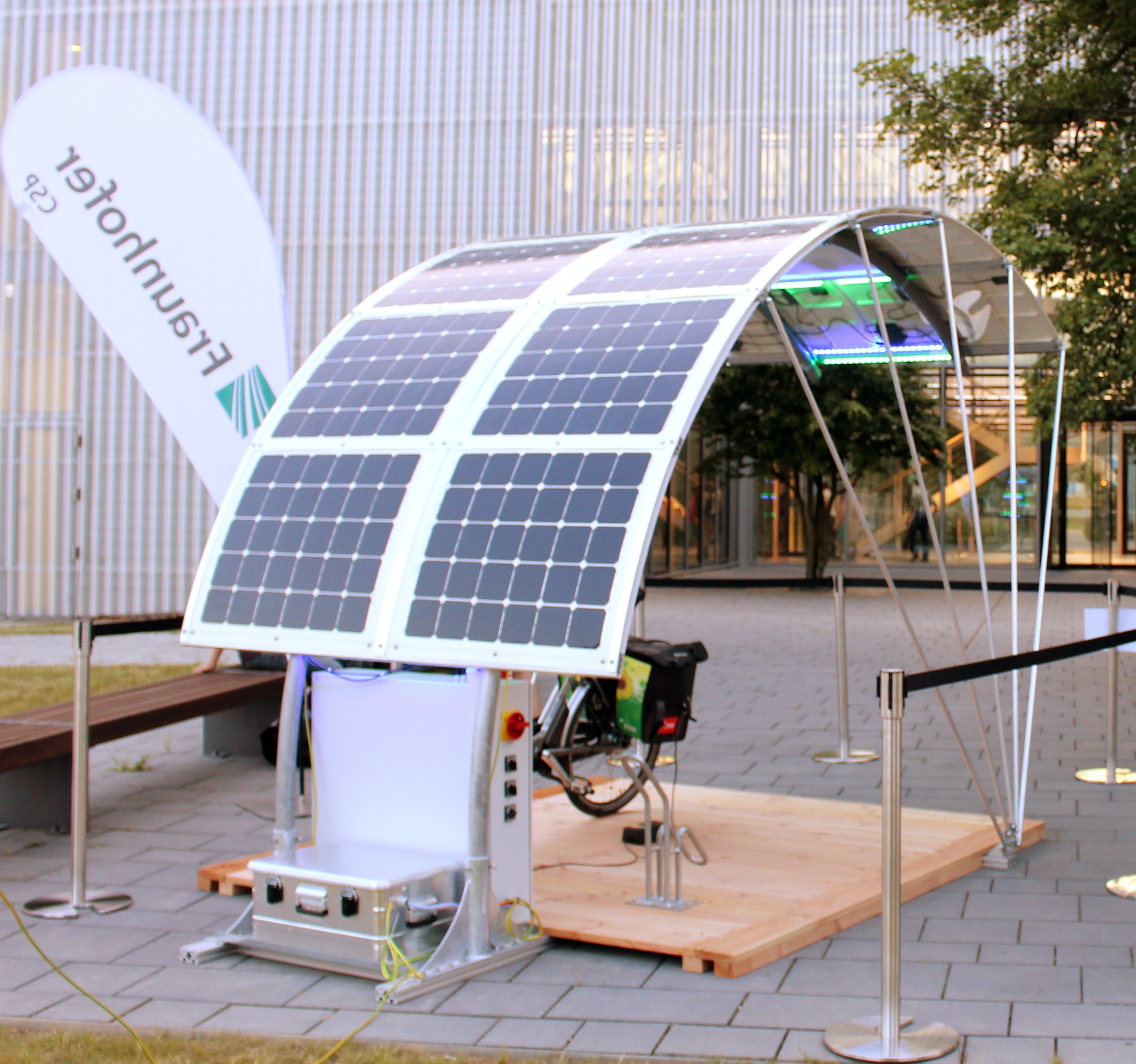

Bike Port in Lightweight Construction

We designed a bike port in lightweight construction in order to combine the operational fields »lightweight construction« and »photovoltaics«. The prototype shows how an appealing design and a concomitant utilization of solar energy can be realized by highly efficient crystalline solar cells, apart from protecting parked bicycles against rain and sunshine.

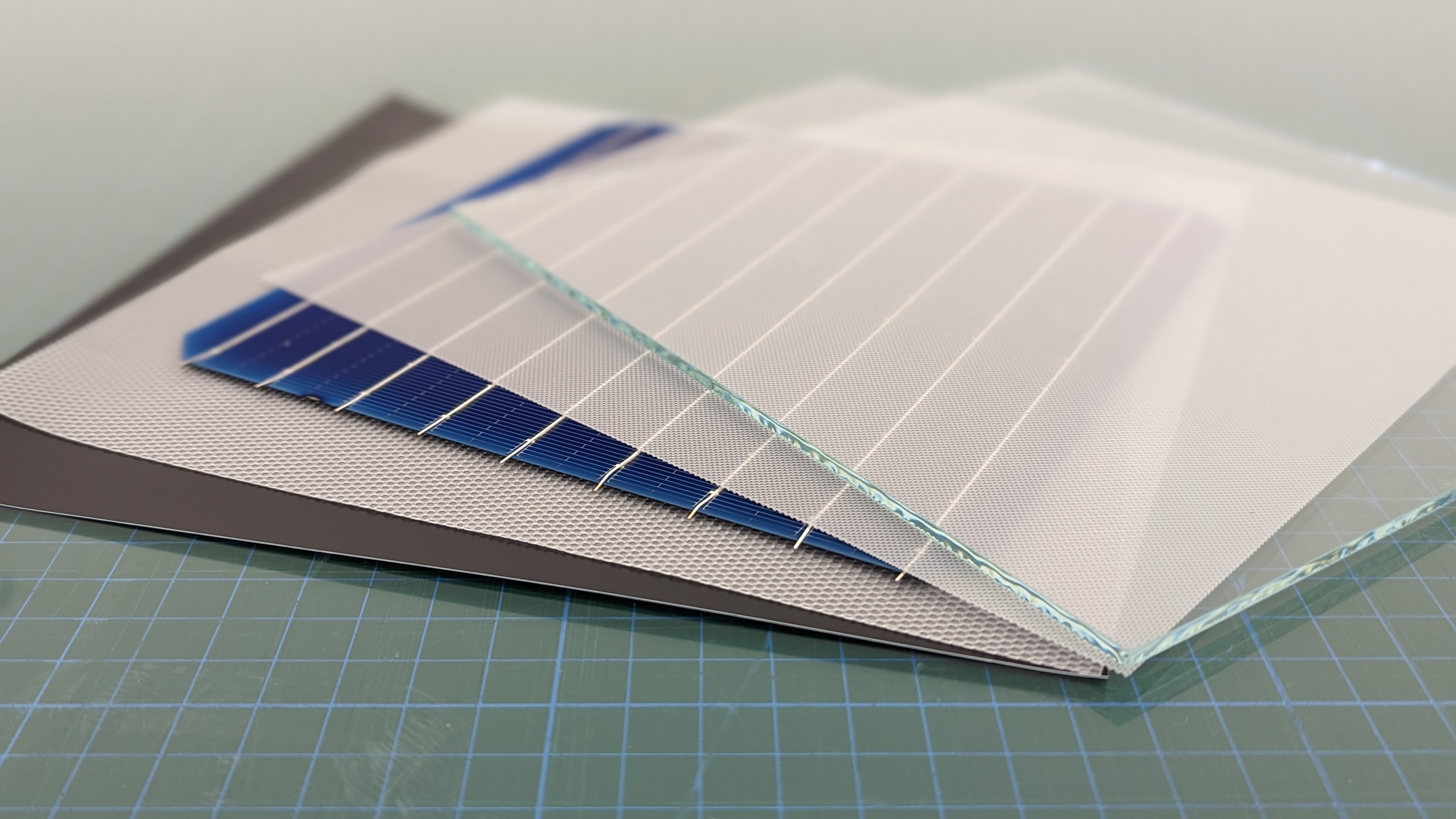

Building-integrated SolarModule GiSMo

Our roof-integrated solar module system developed for the mass market combines the function of a roof coverage with photovoltaics in one product. The innovative shingle system, which relies on the overlap of the singe lightweight solar module carriers, compensates for seasonal roof expansions. The channels built into the overlapping areas enable the runoff of penetrating water as is usually the case with standard roof tiles, but not with other in-roof solar systems. The concept has advantages also when it comes to its rapid installation and exchanging the solar modules. In the overall costs for a roof-top solar system the actual solar modules make up approximately 22-25 percent of the price, while the remaining costs are incurred by additional elements and the often sophisticated installation. The weight of less than 9 kg/m2 per lightweight construction module accounts for an easy handling on the roof.

Equipment

- Glass washer

- GTA Glastechnik-Anlagenbau GmbH | up to 2,2 x 2,6 m²

- Cell string layup

- USK Karl Utz Sondermaschinenbau GmbH | up to 12 cell strings

- USK Karl Utz Sondermaschinenbau GmbH | up to 12 cell strings

- Stringer

- Komax Xcell X3 induction soldering | 5bb G1/M3, full cell, half cell

- TeamTechnik LAB i8 ECA | 9bb M6, ull cell, half cell, shingle

- Komax Xcell X3 induction soldering | 5bb G1/M3, full cell, half cell

- Laminators

- Meyer Solar Solutions GmbH ICOLAM 28/26 | usable chamber size 2,6 x 2,2 x 0,04 m³

- Meyer Solar Solutions GmbH ICOLAM 10/08 | usable chamber size 0,9 x 0,7 x 0,03 m³

- SM Innotech INCAPCELL 18-9 | usable chamber size 1,8 x 0,9 x 0,3 m³

- Manual framing and socket assembly

- Module characterization

- Polymer analytics

- Process analysis and failure diagnostics

- Microstructure diagnostics

- Artificial weathering

- FEM simulation

Fraunhofer Center for Silicon Photovoltaics CSP

Fraunhofer Center for Silicon Photovoltaics CSP