We provide comprehensive electrical contact evaluation, custom process characterization, and root cause analysis services for defects, especially electrical circuitry, to improve the performance and reliability of your systems.

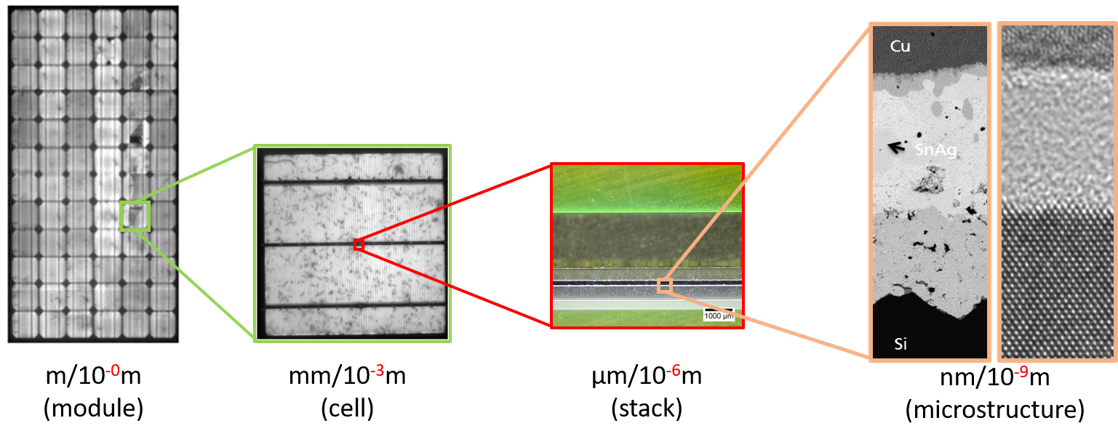

Microstructure Diagnostics

Structure Detection

The function, mode of operation and condition of the interconnection in the module can be detected and classified non-destructively.

Material-property Correlations

- Broad portfolio of non-destructive testing methods

- Power measurement, EL, thermography, current flow imaging, X-ray technology (2D and 3D) as well as optical and ultrasonic microscopy

- Correlation of properties with material analysis and physical simulation

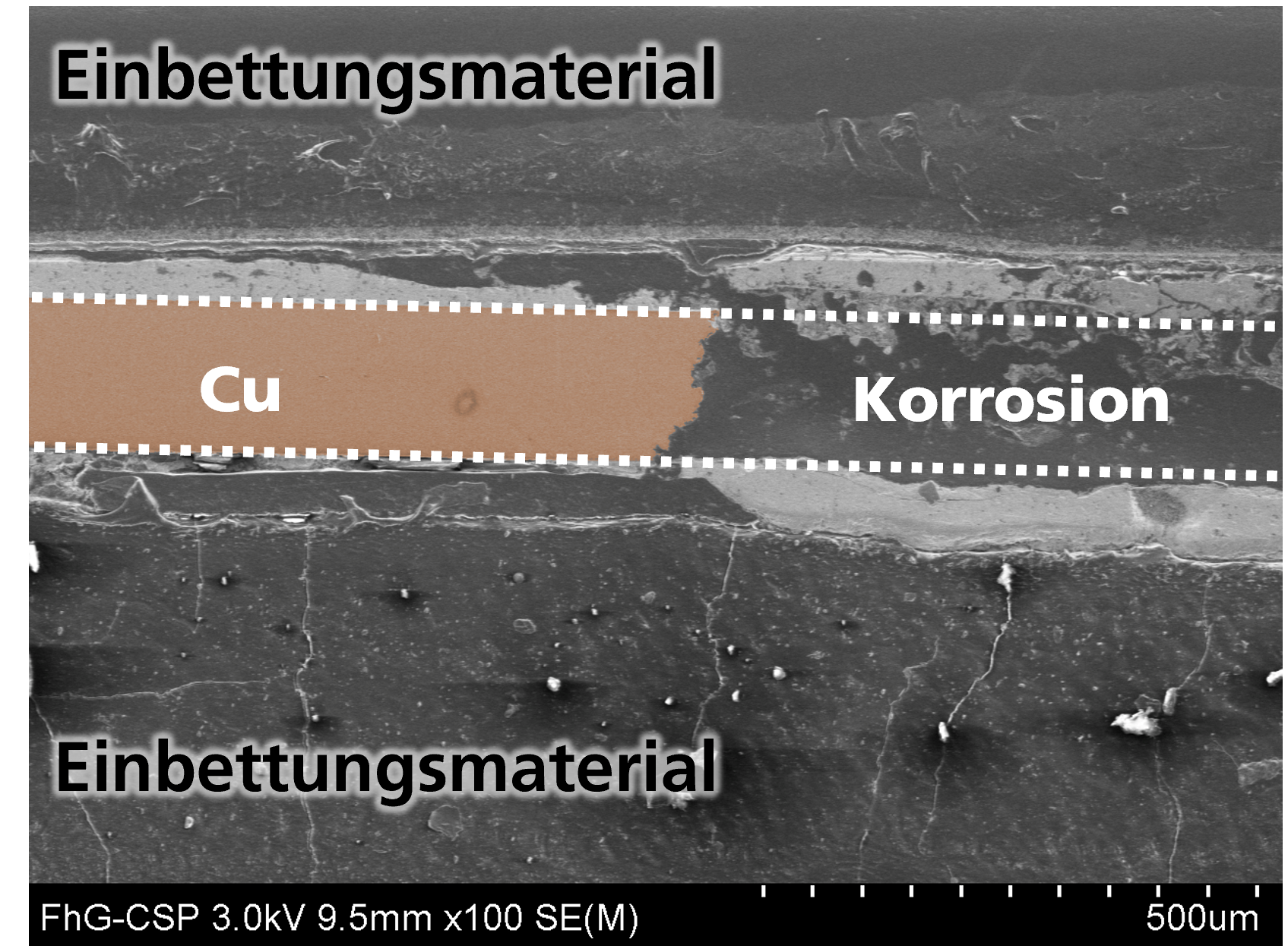

Quantification of structure, size and composition by analytical electron microscopy is essential for the robust evaluation of contact systems.

Analytical Microstructure Analysis

- Preparation portfolio for artifact-free target preparation down to µm range - basic requirement for reliable measurement results

- Measurement of structure, size and chemical composition

- Measurement methods: SEM/FIB, TEM, EDX, EBIC, AFM, XPS, TOF-SIMS, Raman, FTIR

Process Analysis and Failure Diagnostics

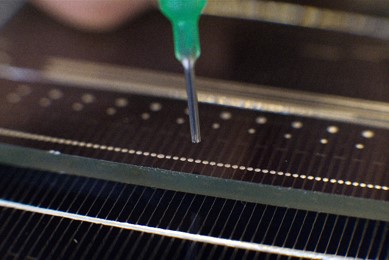

Conductive adhesives for contact formation by means of a low-temperature process for temperature-sensitive solar cells or as an alternative to the classic soldering process.

Support of Module Development

- Status assessment of electrical contacts

- Recognize process influences

- Understanding contact formation

- Improve resource efficiency

Fraunhofer Center for Silicon Photovoltaics CSP

Fraunhofer Center for Silicon Photovoltaics CSP