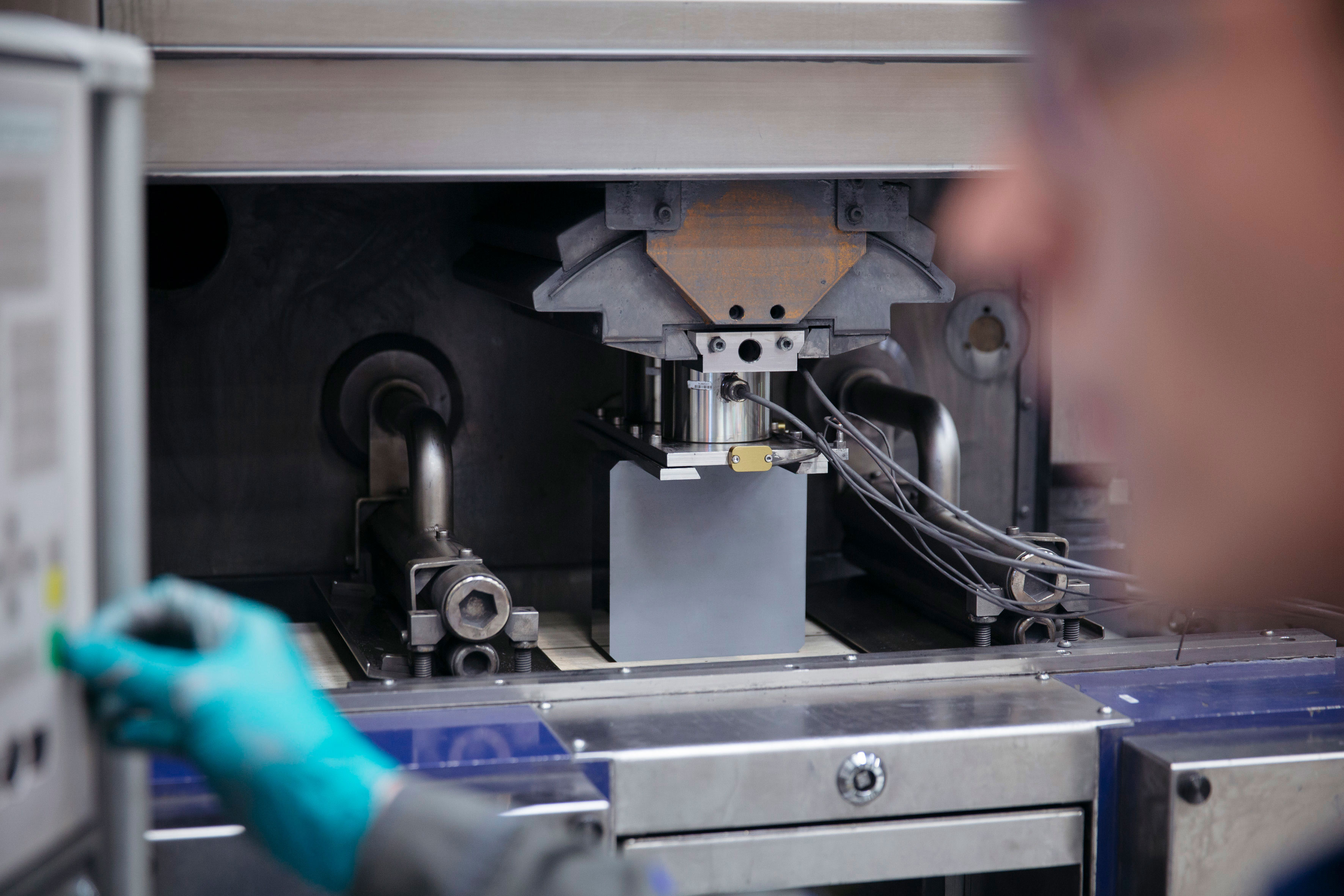

We offer a finishing and manufacturing of brittle-hard materials for customers from various industries. The core areas of our R&D services are silicon crystal processing and the plasma treatment of wafers. In the field of silicon crystal processing, we offer all processing steps from mono or multicrystal to cleaned and inspected wafers. The manufacturing processes are not limited to silicon. Sawing of silicon carbide or sapphire is also possible.

Companies with a focus on wafer production or material processing are to be addressed by our range of services.

We offer:

- Processing of hard-brittle materials

- Wafering (diamond wire and slurry process) of silicon, silicon carbide, silicon nitride and sapphire

Fraunhofer Center for Silicon Photovoltaics CSP

Fraunhofer Center for Silicon Photovoltaics CSP