At Fraunhofer IMWS, we are dedicated to advancing hydrogen technologies through comprehensive diagnostics of materials. Our focus lies in understanding the critical interplay between material properties and how they influence the performance of electrolyzers and fuel cells. By bridging the gap between theoretical research and practical application, we aim to drive innovation and enhance the quality, efficiency, and sustainability of hydrogen systems.

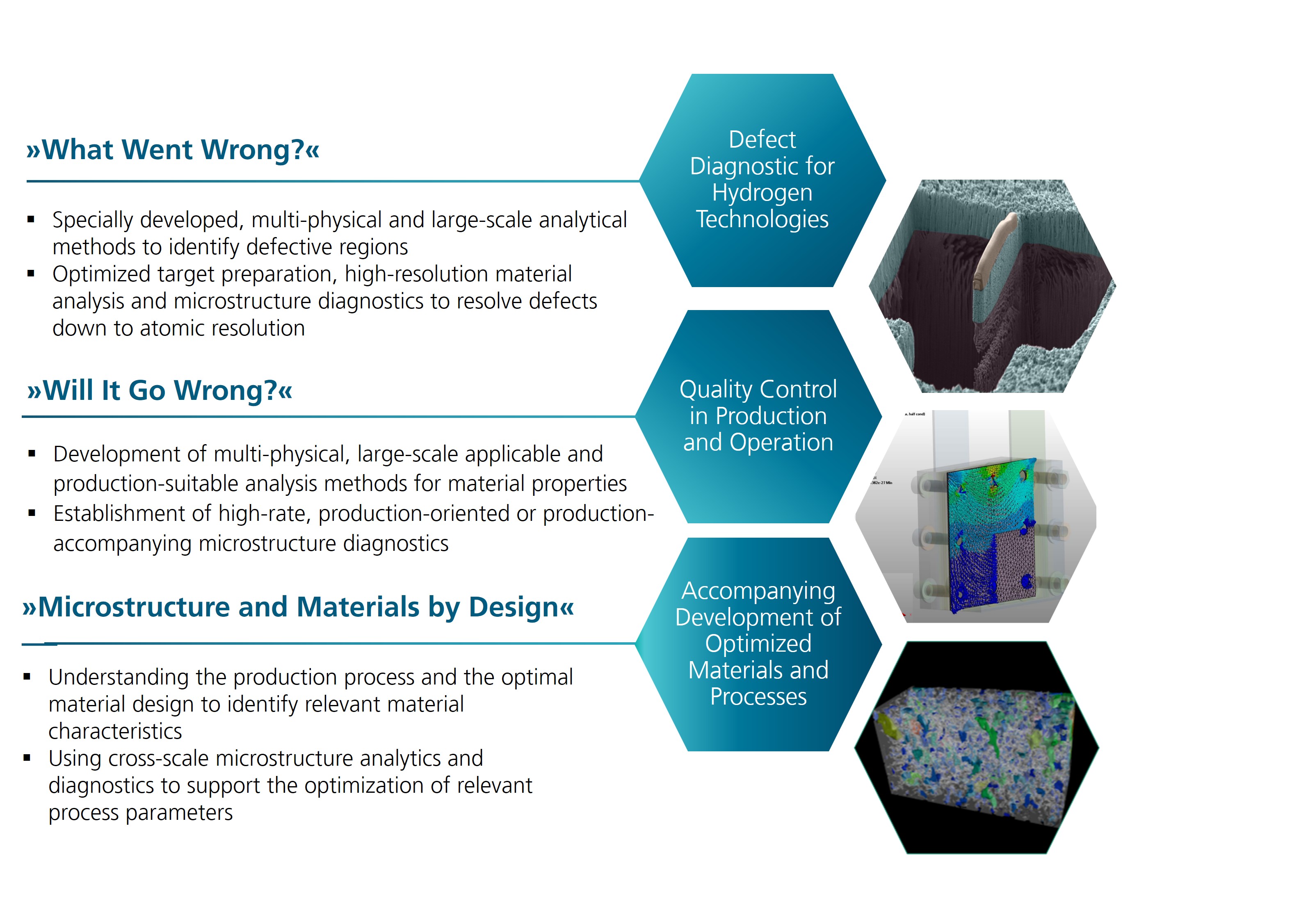

Key areas of expertise include:

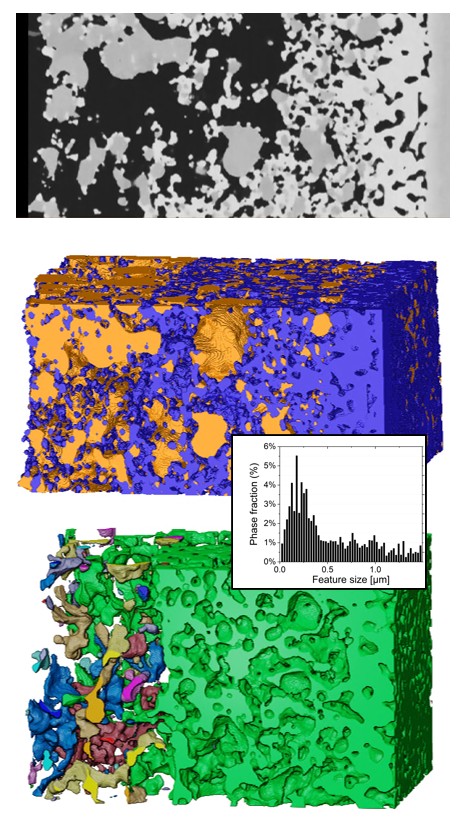

- Material Characterization: In-depth analysis of material properties and behaviors

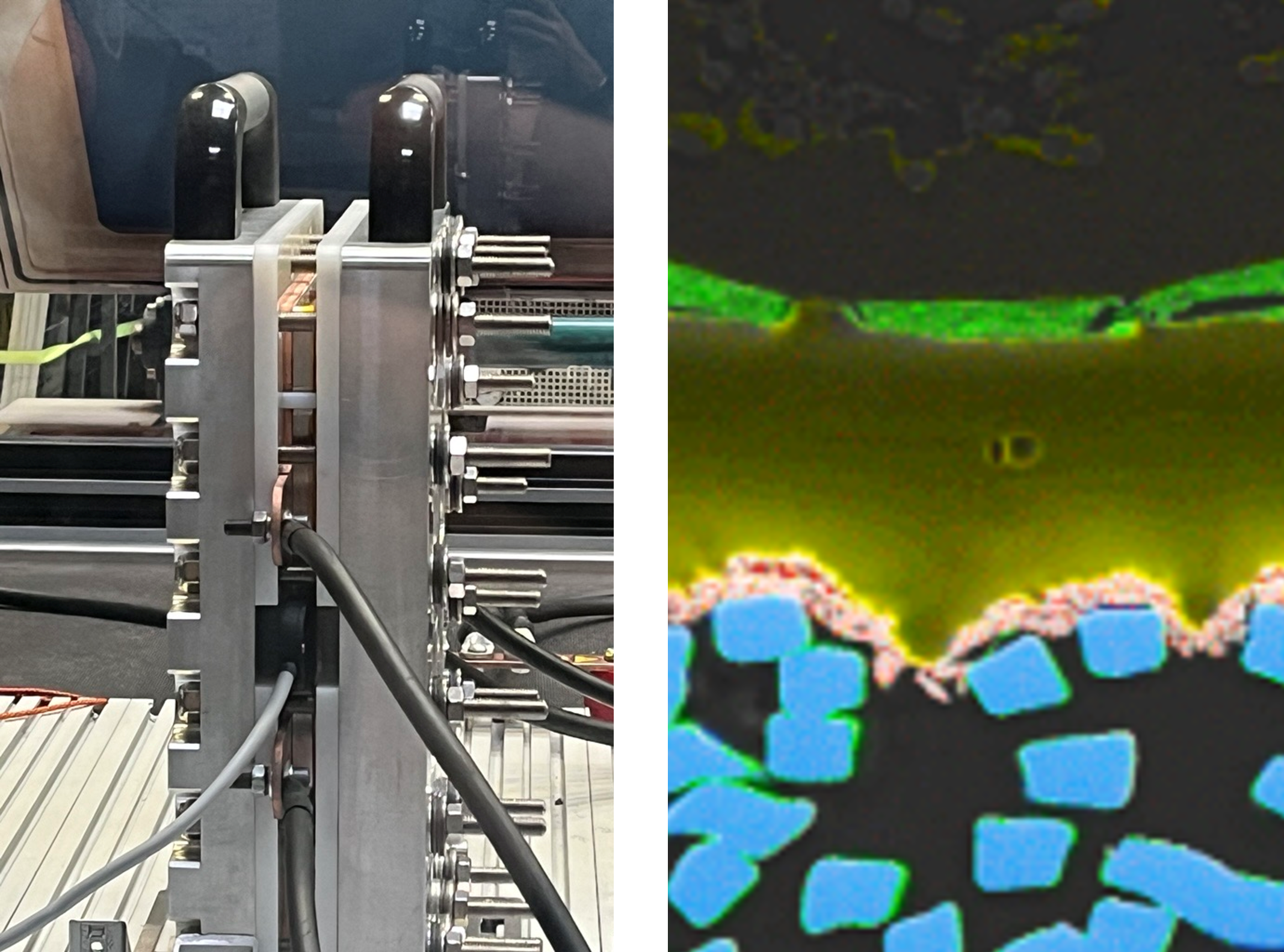

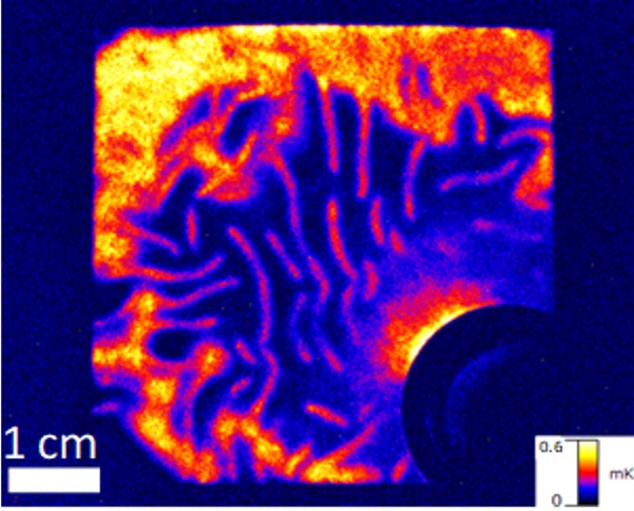

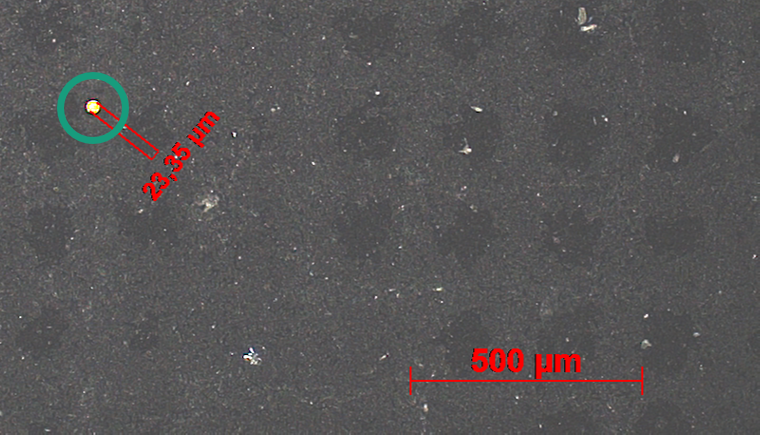

- Defect Diagnostics: Identification and avoidance of defects at the micro and nano scale

- Quality Control: Ensuring the reliability of materials in production and operation

- Optimized Processes: Supporting the development of materials and processes tailored to hydrogen technologies

We cover expertise for all hydrogen technologies such as

- PEM: Proton Exchange Membrane electrolysis

- AEM: Anion Exchange Membrane electrolysis

- SOEC/SOFC: Solid Oxid Electrolyzer/Fuel Cells

- AE: Alkaline electrolysis

Fraunhofer Center for Silicon Photovoltaics CSP

Fraunhofer Center for Silicon Photovoltaics CSP