Electroluminescence and Thermography Investigations

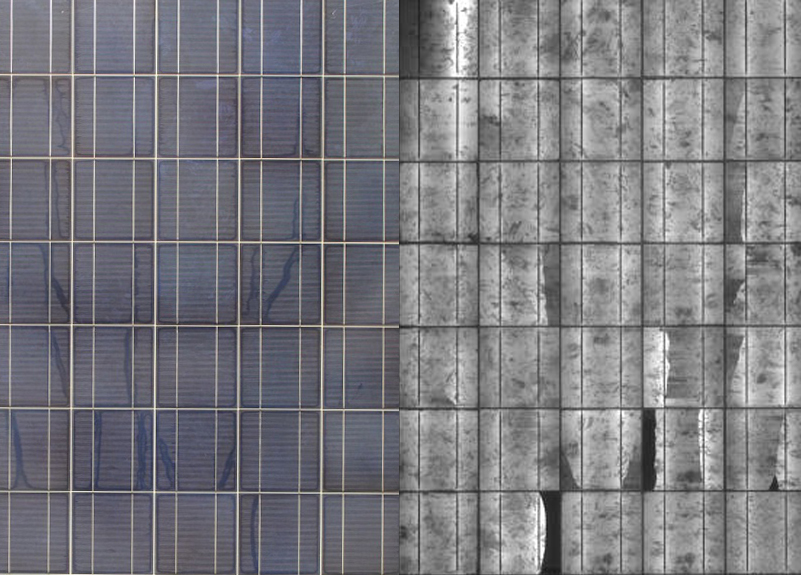

Destruction-free methods are usually the beginning of an error analysis. They allow the classification of defects with respect to electrical relevance and a first assessment of the nature of the defect. Lastly, a first localization of the defect origin is possible.

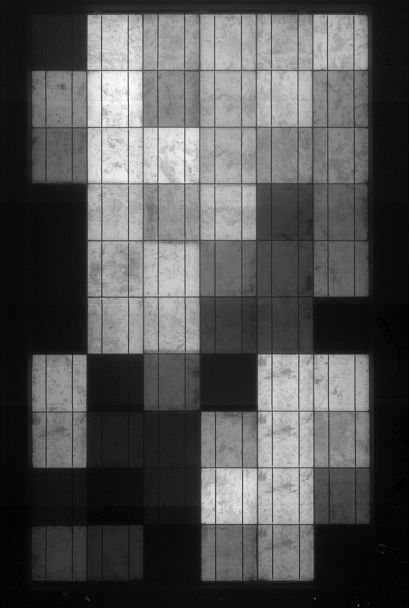

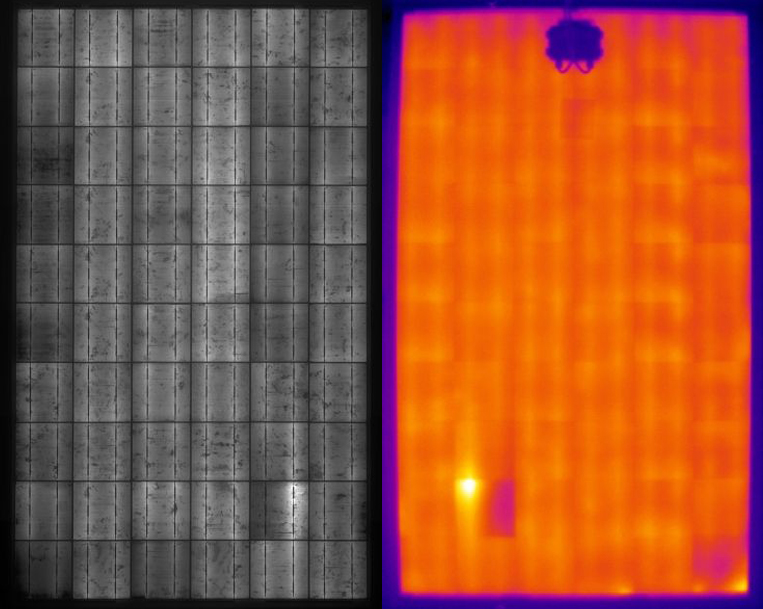

Electroluminescence, for example, allows to distinguish between the electrically active and less active regions in the module (for example as a result of cell breakage, connector breakage, light degradation) and to investigate parallel resistance problems (for example as a result of PID, short circuits, light degradation).

Thermographic methods also enable identification of series resistance problems and hot-spot detection.

Fraunhofer Center for Silicon Photovoltaics CSP

Fraunhofer Center for Silicon Photovoltaics CSP