ICP-MS Trace Analysis – Reliable Results for Maximum Material Purity

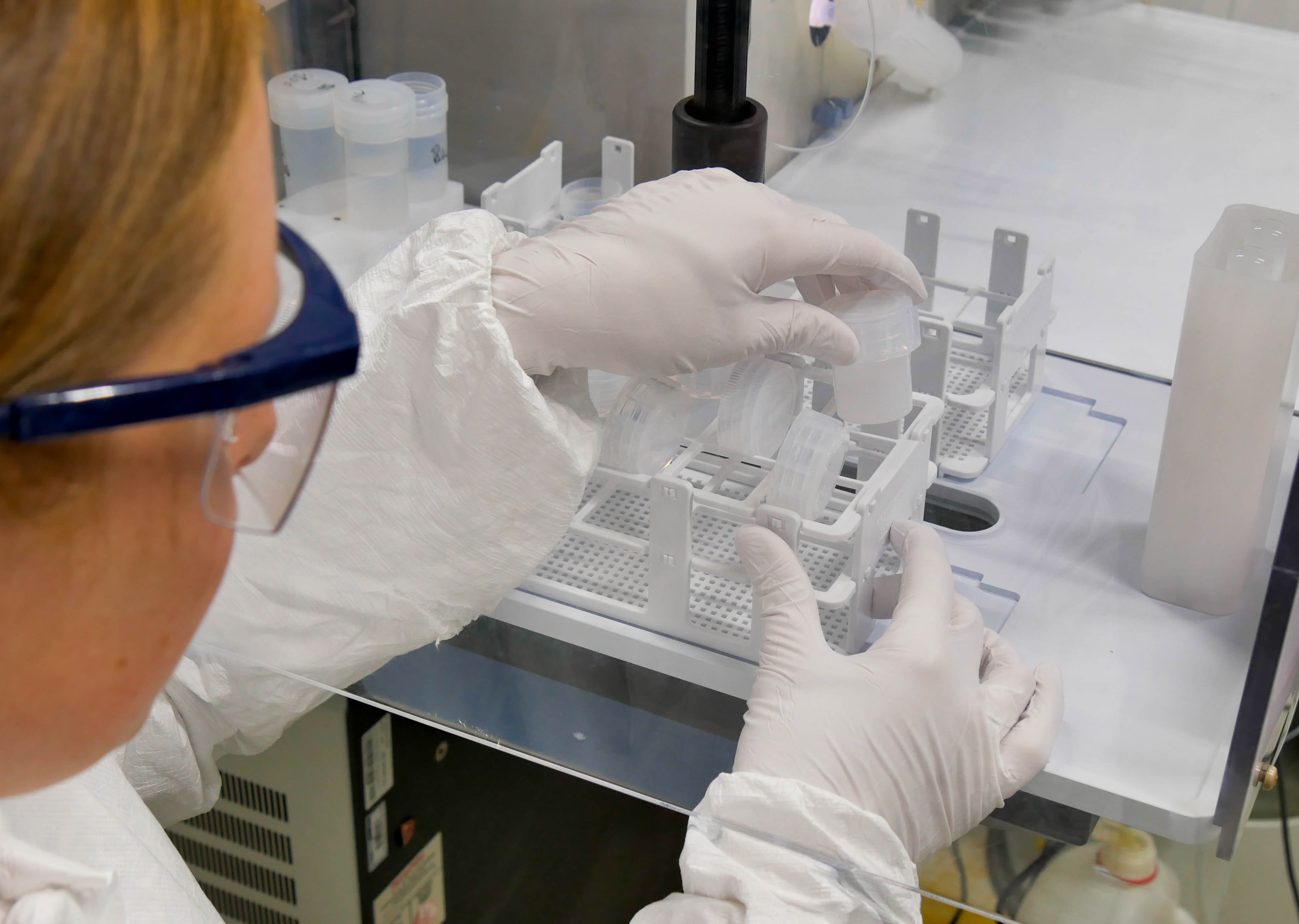

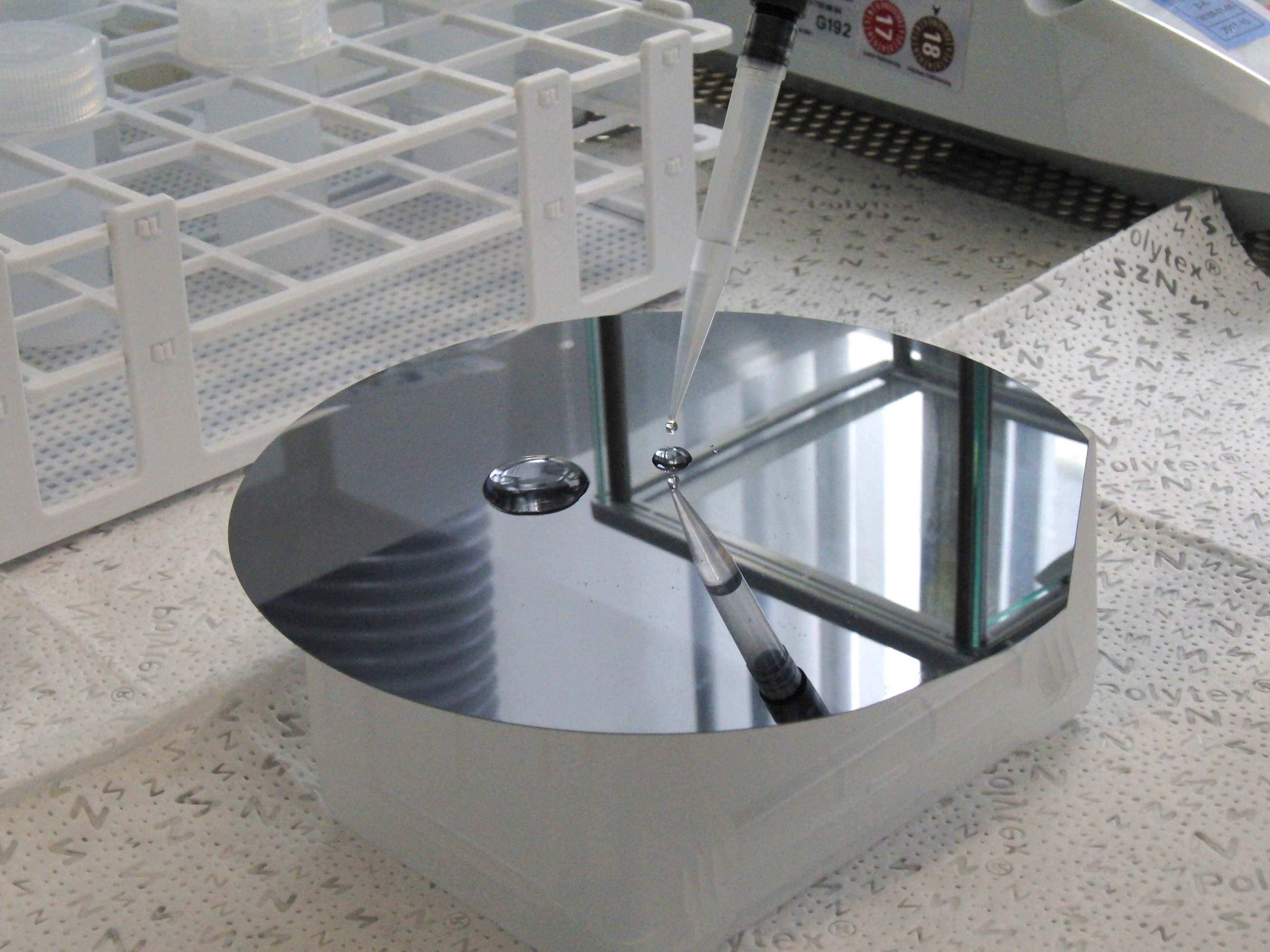

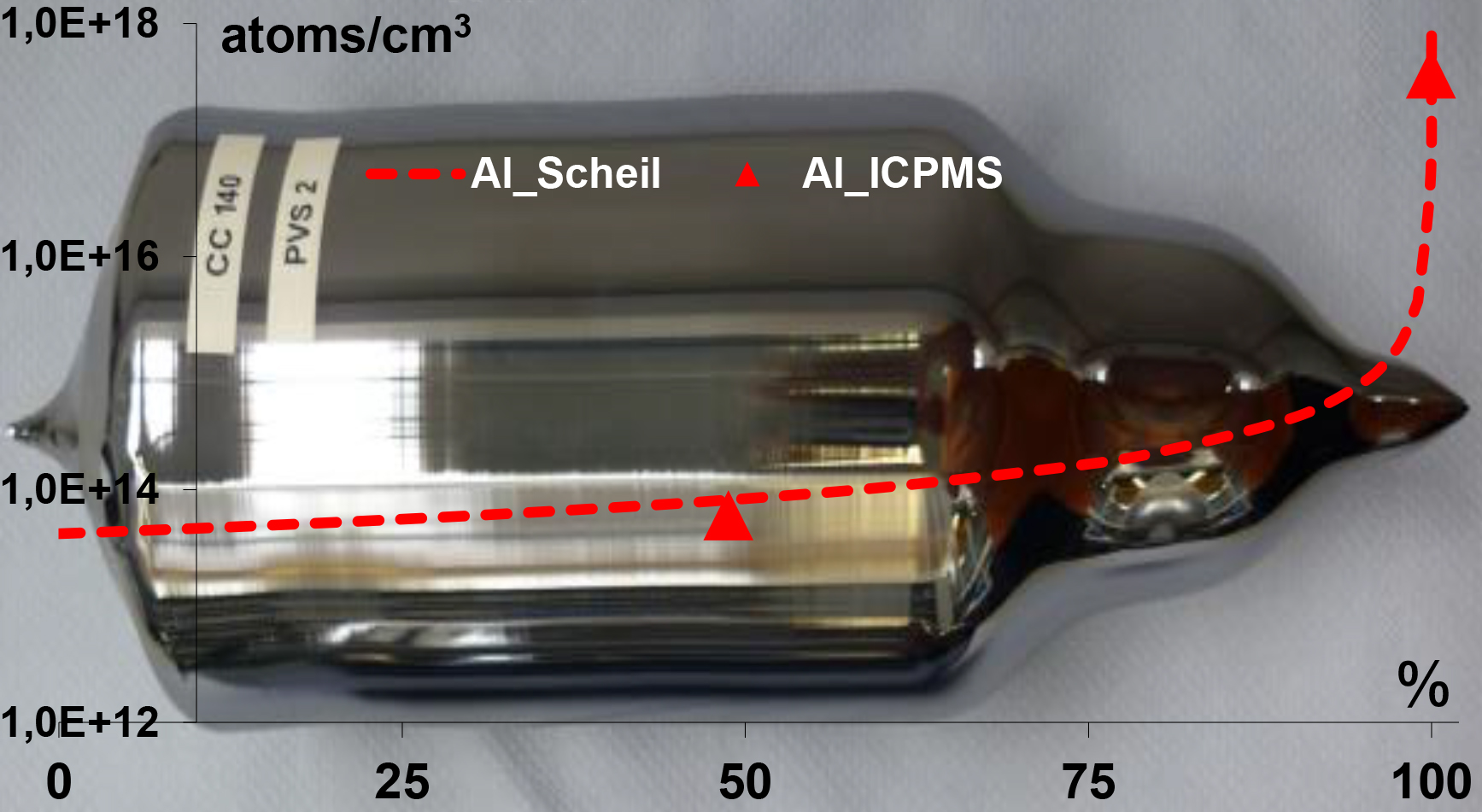

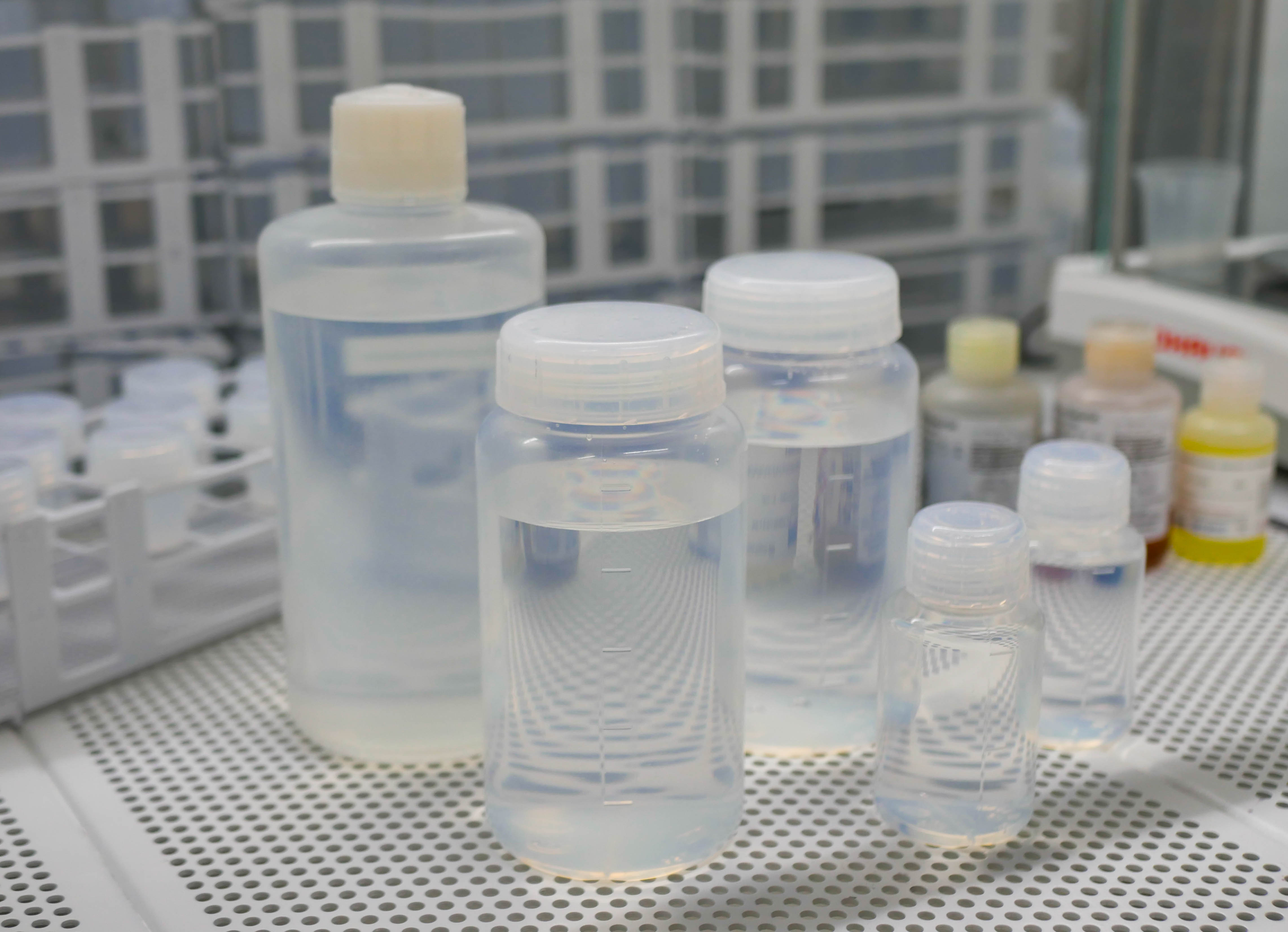

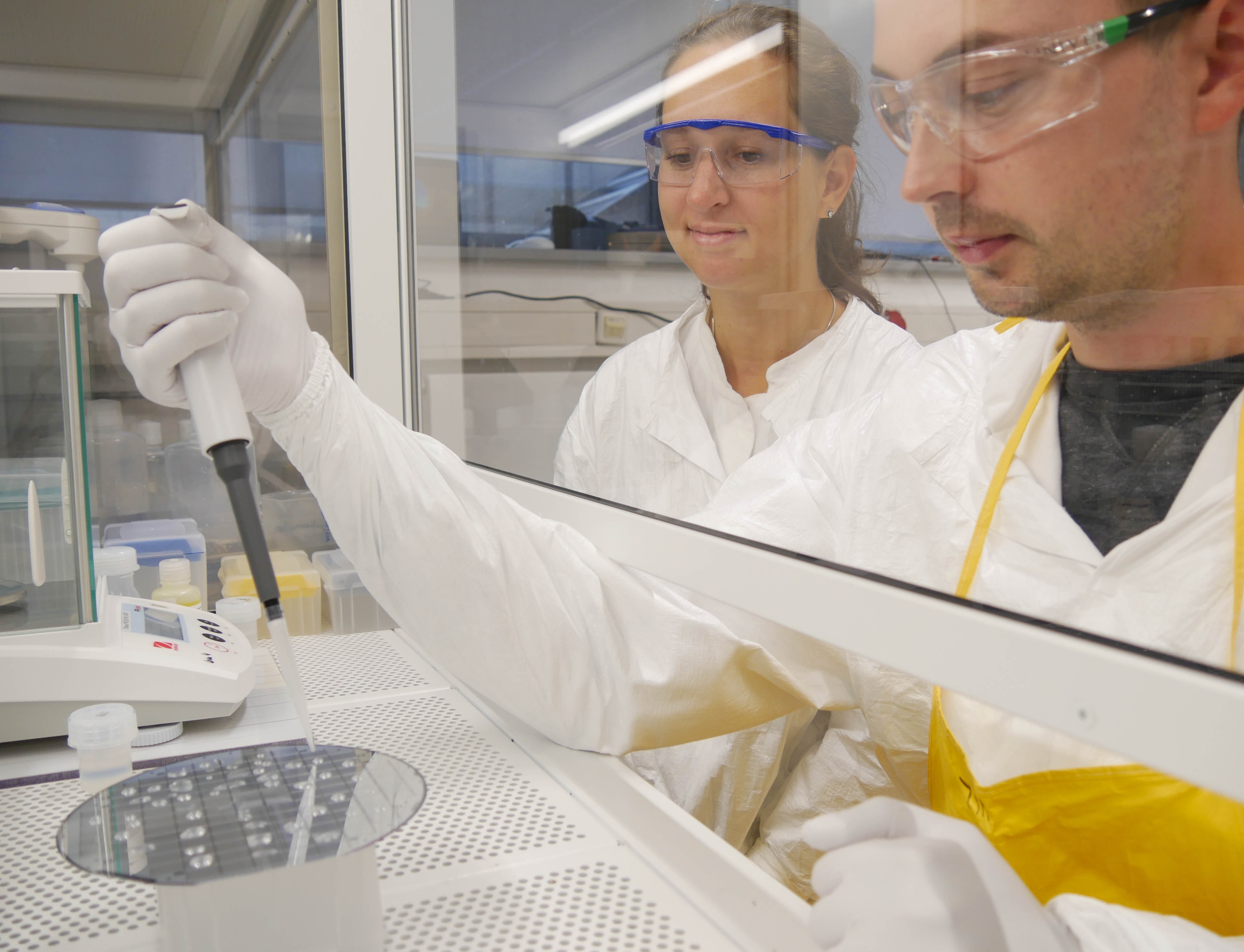

When the highest purity is essential, ICP-MS analysis delivers precise data down to the ppt range. This method enables the reliable detection of even the smallest amounts of inorganic impurities – especially metals. We support you in quality assurance, process control, and research.

What we offer:

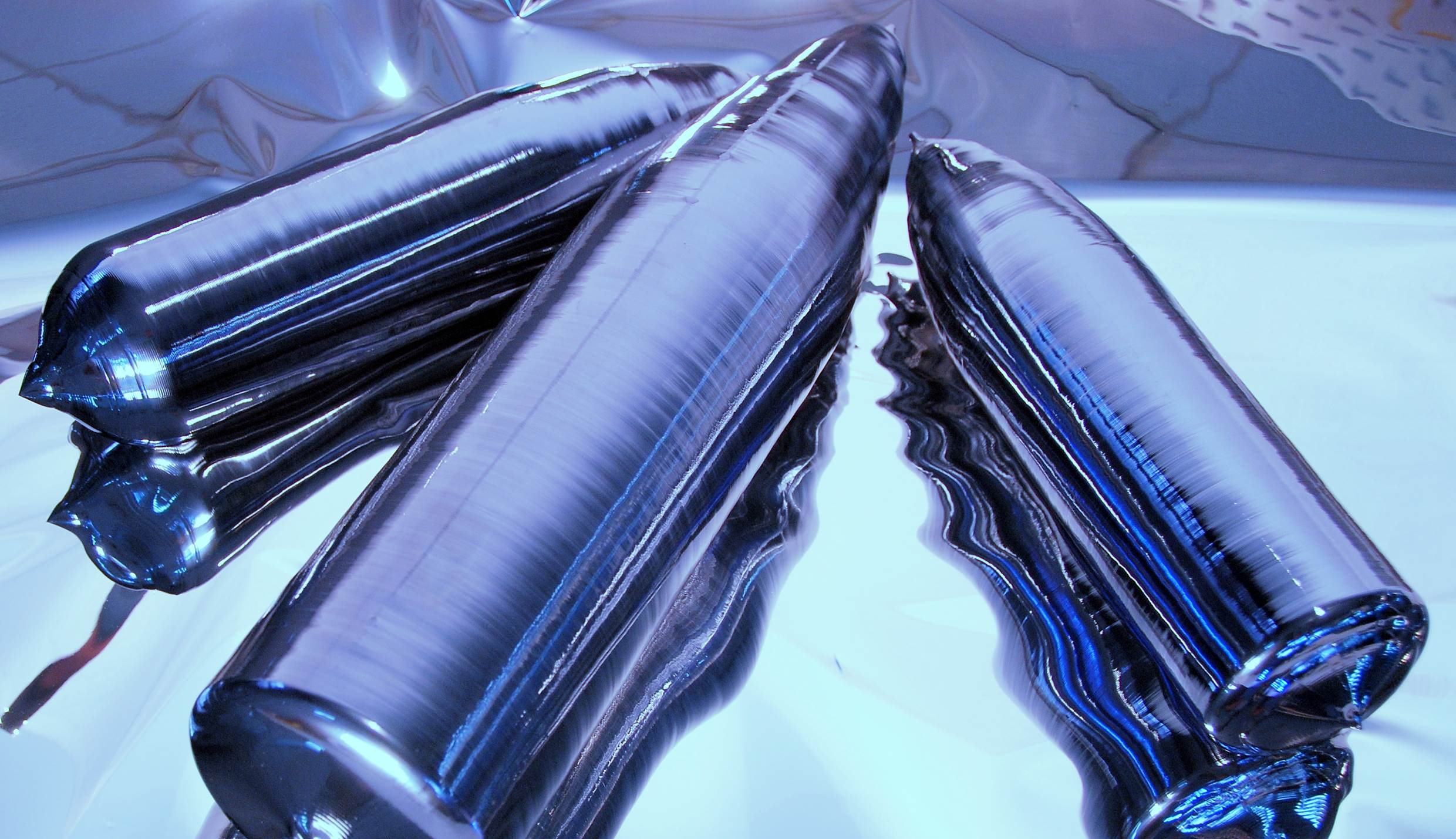

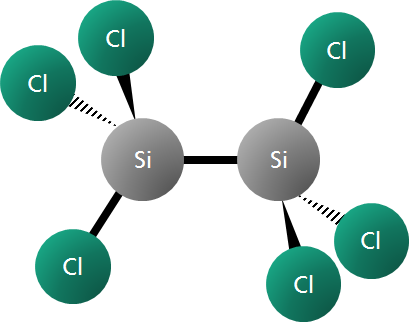

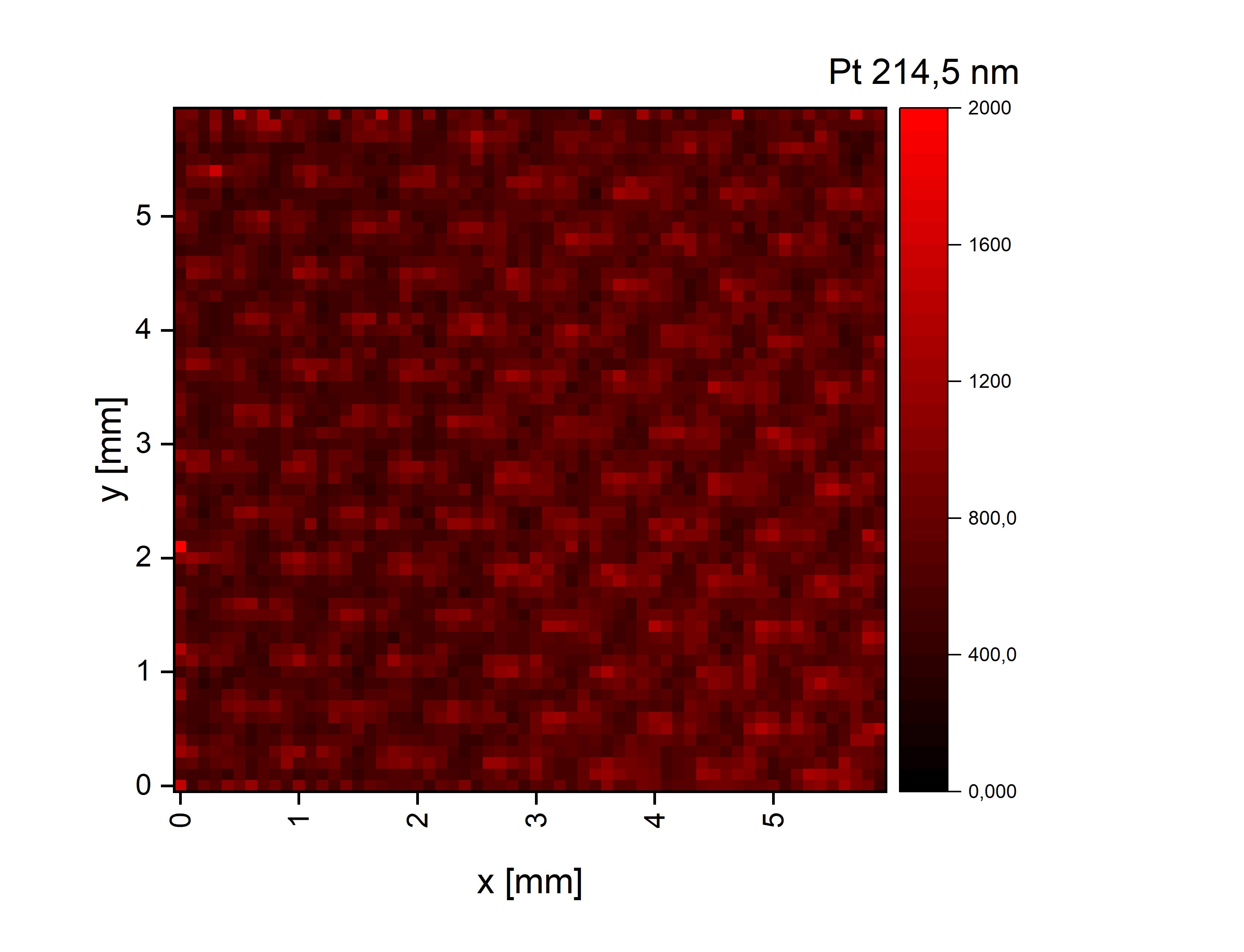

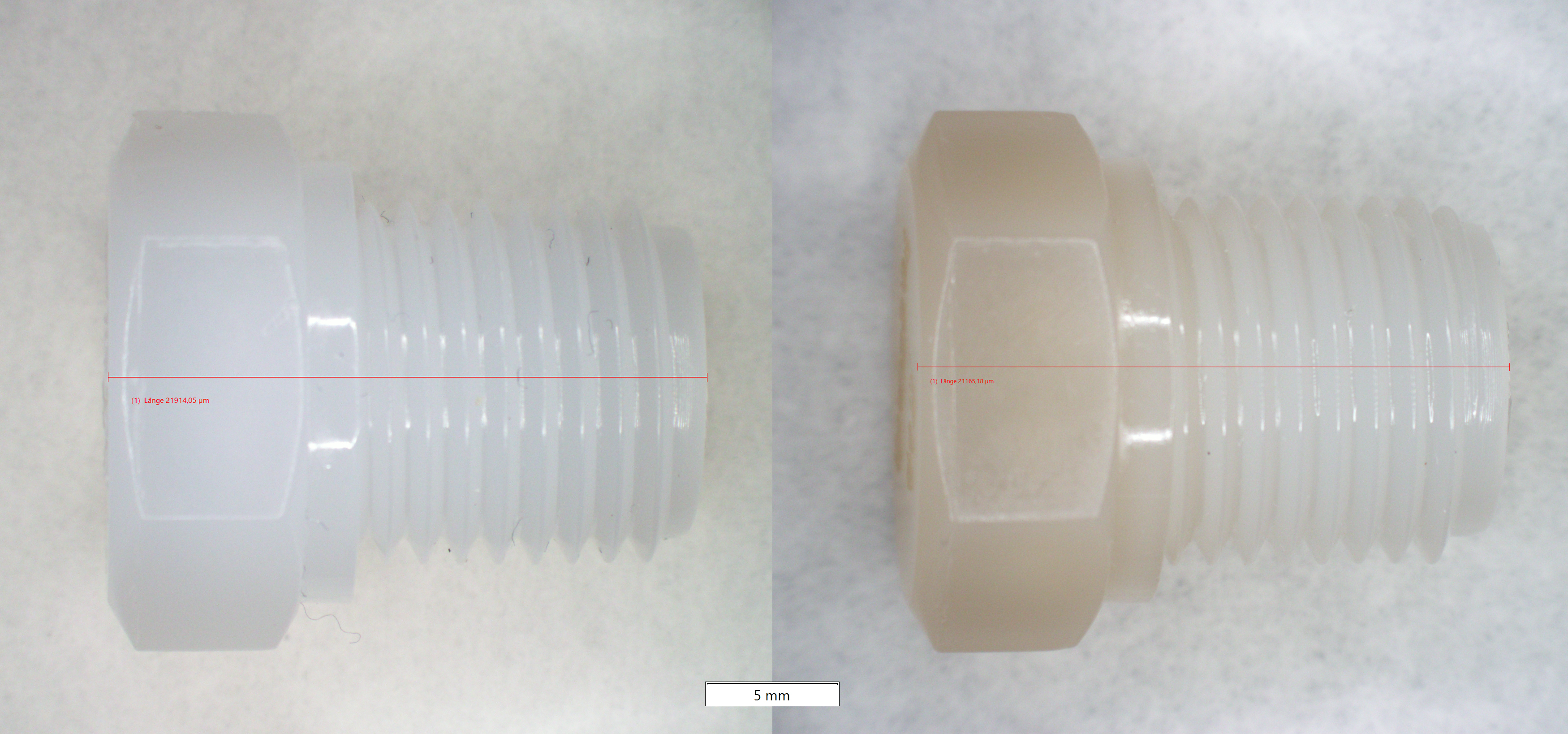

- ICP-MS analysis of a wide range of materials such as silicon, silanes (HCDS, STC, TCS…), quartz glass, silicon carbide (SiC), fuel cells (CCMs), and more

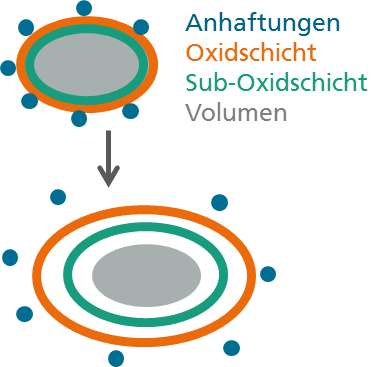

- Detection of metallic impurities and trace elements on surfaces and inside your samples (bulk analysis)

- Detection limits down to the low ppt range – for maximum sensitivity and accuracy

Your benefit:

With our precise trace analysis, you ensure the quality of your products, detect impurities at an early stage, and optimize your processes.

This helps you protect your brand, improve product quality, and minimize risks.

Our research facility is certified according to DIN ISO 9001.

Watch the video below to get an impression of our analytical services. Contact us for a personalized consultation – we’ll help you achieve your quality goals!

Fraunhofer Center for Silicon Photovoltaics CSP

Fraunhofer Center for Silicon Photovoltaics CSP