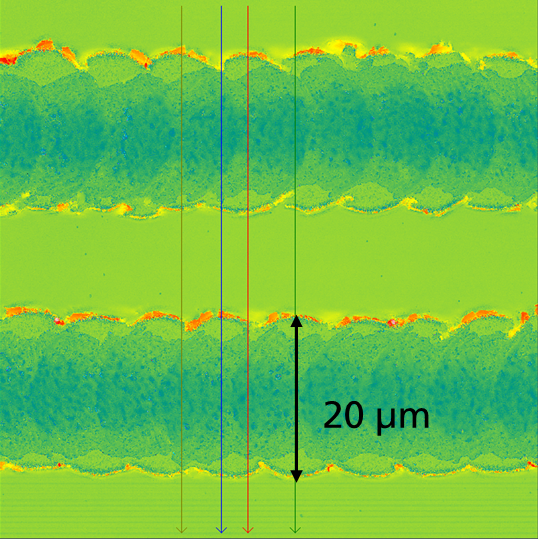

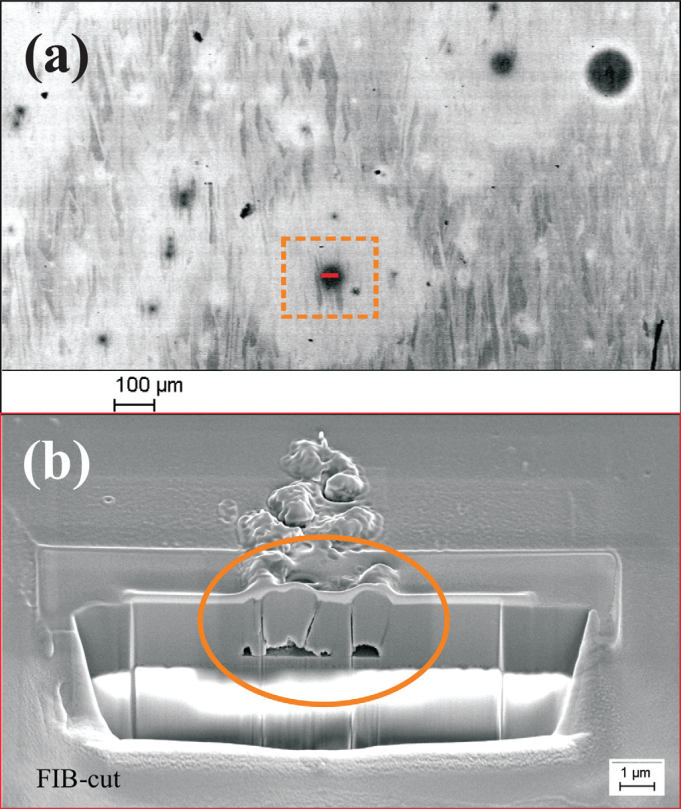

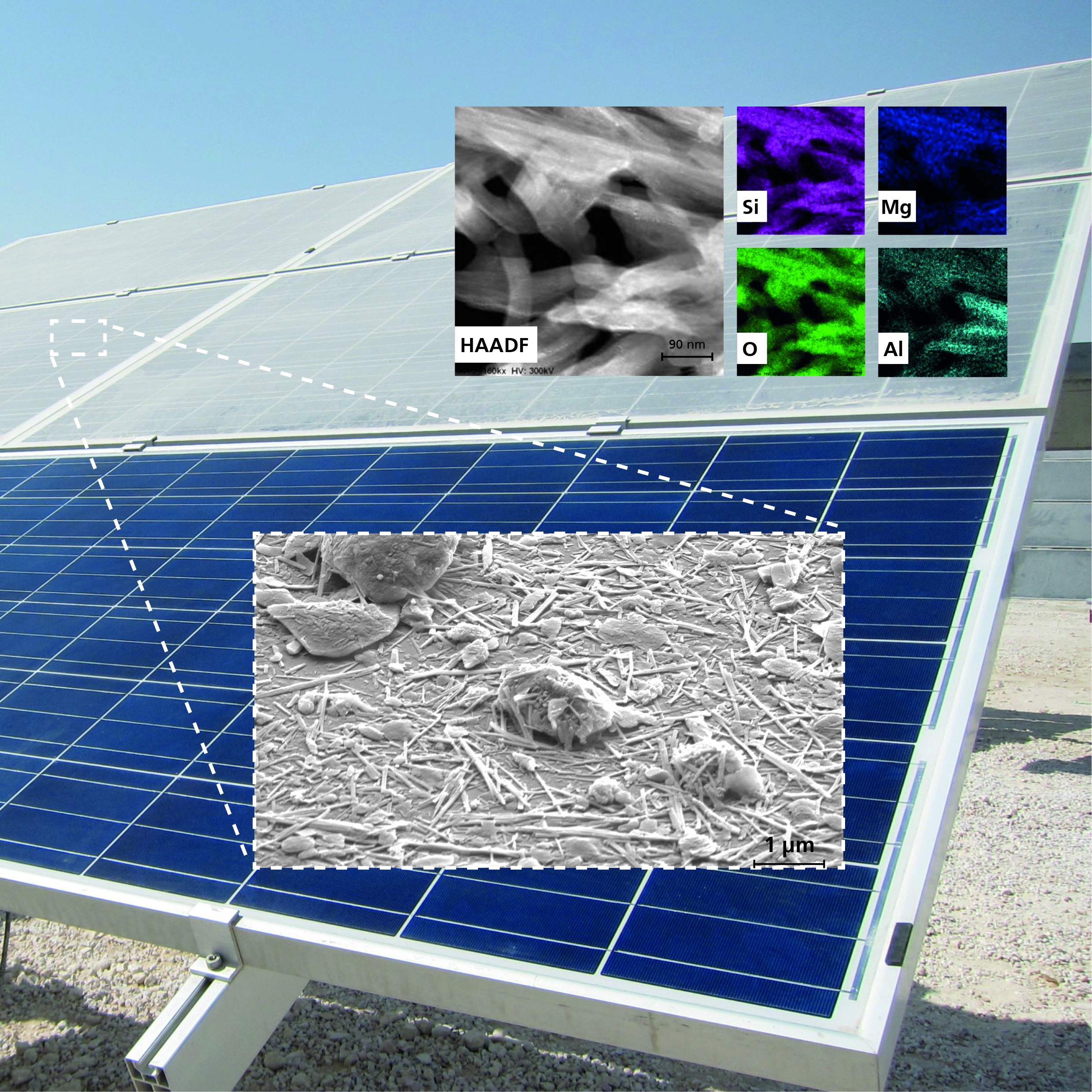

Failure diagnostics and nanoscopic examinations of thin-film solar modules require extremely high-resolution analytics. Electrical, optical and microstructural methods are continuously further developed in order to evaluate processes and materials in thin-film photovoltaics (CdTe, CIGS, Si, OPV). We determine the reliability of thin-film solar modules based on spatially resolved yield/loss analyses and analyze the cause of failures in open-field and laboratory installations. We design and manufacture special test structures by applying laser structuring and coating technology.

Partners from the PV industry, plant operators, and equipment manufacturers are the ones who define the R&D objectives. By applying electro-optical localization and preparation methods and material-scientific analytics, the causes for defects can be elucidated down to their atomic dimensions in a very short time. Based on a fundamental understanding of the processing conditions and the resulting electrical properties of the material the team Thin Film Characterization develops proposals for »inline« diagnostics.

Fraunhofer Center for Silicon Photovoltaics CSP

Fraunhofer Center for Silicon Photovoltaics CSP