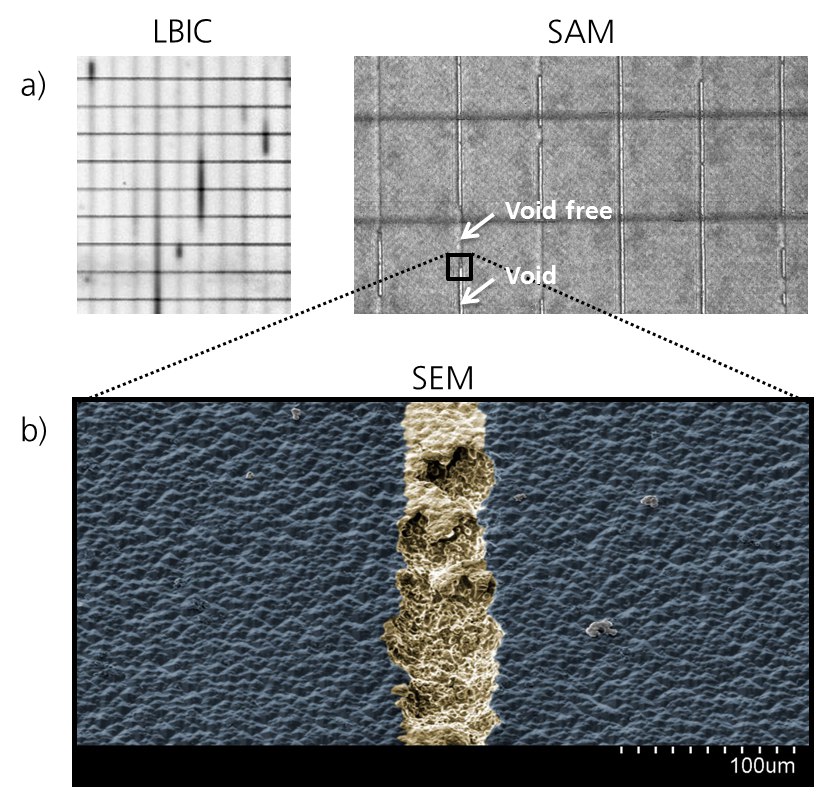

Silicon solar cells with a full-surface aluminium back contact, which currently have the largest market share, will be replaced by PERC technology in a few years' time. With this technology, the efficiency of the solar cells is significantly increased, in which the aluminium back contact is not located over the entire surface but locally and thus enables passivation of the reverse side. The changed structure results in fundamentally new defect patterns for this cell type and thus changes the criteria for quality assessment in comparison with the current standard solar cells. This applies to errors that occur directly in production, such as incomplete backfilling of the back contacts, so-called "PERC voids". However, long-term stability may also be impaired by new degradation mechanisms, e. g. by light-induced degradation of multicrystalline PERC solar cells. In order to determine the cause of these defects, electrical and microstructural characterization techniques are combined at the Fraunhofer CSP and test methods for the reliable evaluation of PERC cells are made possible.

For the test "Voids" in a solar cell, methods for fast and non-destructive detection have been successfully tested. With these methods,"voids" can be quantified in terms of their frequency and their electrical losses. Furthermore, a method has been developed to map the affected back contact over large areas with regard to the distribution of its local back-surface field (BSF). The BSF is necessary for a low-loss passivation of the contact, but can degrade by "voids".

In addition to the production-related defects in PERC solar cells, long-term stability under realistic environmental conditions is also decisive. A process for the rapid evaluation of light-induced degradation was developed at the Fraunhofer CSP and a patent has been applied for. This enables the dynamics of the various phases of degradation and regeneration processes to be quantified and thus provides information on the long-term stability of solar cells.

Further information:

[1] S. Großer, M. Werner, C. Hagendorf; Microstructure of Void Formation Stages at Local Rear Contacts, Energy Procedia 77 (2015)701 - 706

2] S. Großer, S. Eiternick, M. Turek; Non-Destructive Characterization and Microscopic Properties of Rear Contact Voids in PERC Cells, 31st European Photovoltaic Solar Energy Conference and Exhibition (2015) ISBN 3-936338-39-6

Fraunhofer Center for Silicon Photovoltaics CSP

Fraunhofer Center for Silicon Photovoltaics CSP