Background and Project Objectives

The ecological footprint of the photovoltaic industry is often smaller than that of conventional energy sources. Photovoltaic systems do not produce any harmful emissions during operation and thus contribute significantly to reducing air pollution and greenhouse gas emissions. However, when considering the entire life cycle of solar modules—from raw material extraction to production, use, and disposal—weak points become apparent.

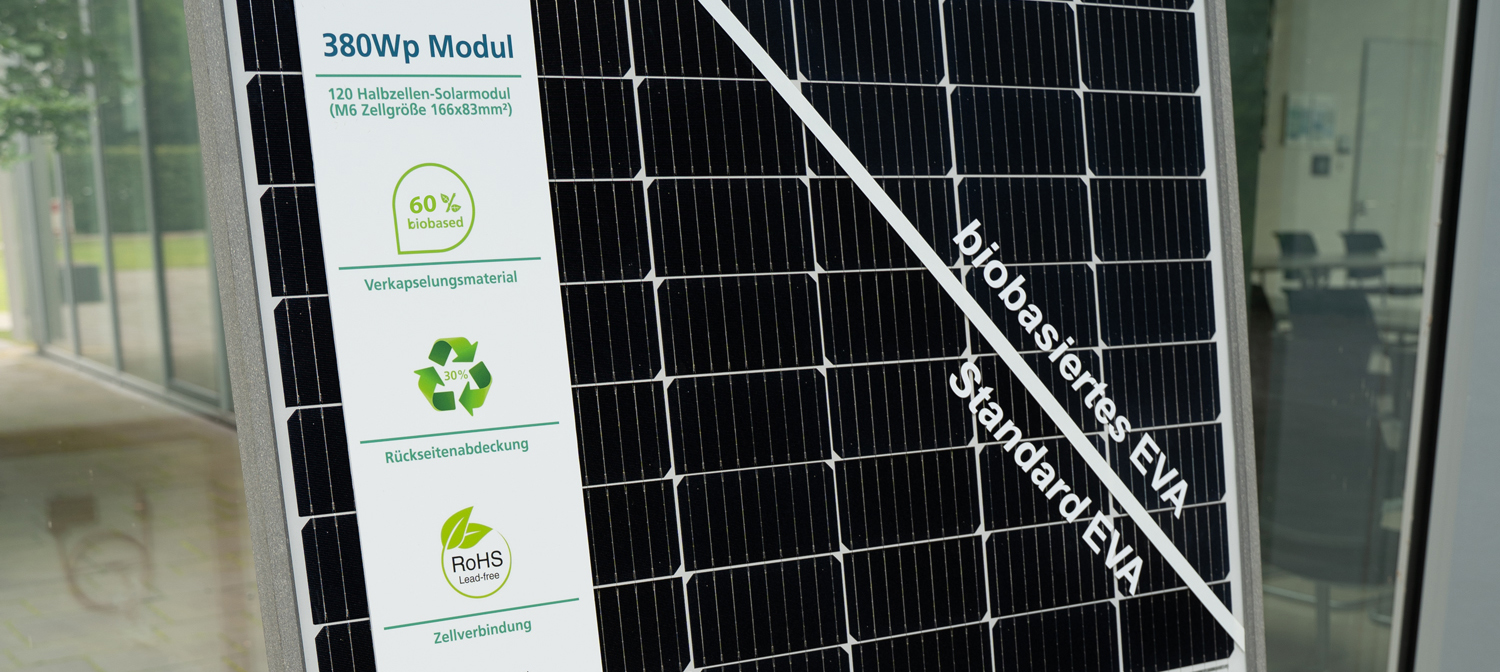

Current photovoltaic modules consist of glass, polymers, metals, and silicon-based solar cells. The extraction of raw materials, especially silicon, can be harmful to the environment. In addition, the individual components are rarely returned to the raw material cycle. At the end of their average operating phase and service life, which currently stands at 20 to 25 years, old PV modules are a waste product that contains valuable materials that are difficult to separate, for which there is currently no solid recycling concept. Most of the components are currently either incinerated or “downcycled” into low-quality products. Approaches that involve manufacturing the materials used from renewable raw materials and simultaneously reintegrating them into the cycle could make the solar industry even greener.

This is where the “E2 – E-Quadrat” project, funded by the German Federal Ministry for Economic Affairs and Climate Protection (funding code 03EE1114), comes in. A team from Fraunhofer CSP, in collaboration with NOVO-TECH GmbH, developed and tested materials that are both highly reliable over the long term in all weather conditions and fully recyclable.

Fraunhofer Center for Silicon Photovoltaics CSP

Fraunhofer Center for Silicon Photovoltaics CSP