Solar modules on rooftops or in fields must be capable of withstanding stresses and environmental impacts such as heavy wind and snow loads. The latter might cause damage. Tests have shown that particularly the fissures in solar cells present a problem frequently encountered in everyday practice. They affect the module's performance and in the worst case cause short circuits. A new method has now been developed at the Fraunhofer-Center for Silicon Photovoltaics CSP to examine the creation of fissures during load exposure and under defined boundary conditions.

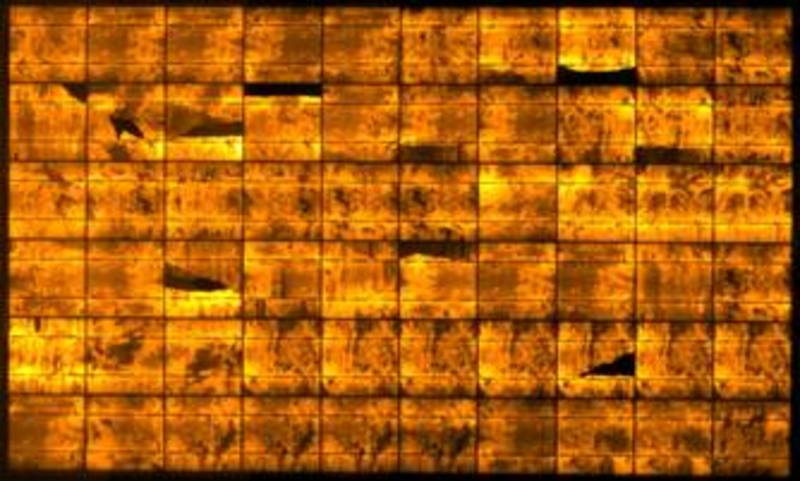

The new method to study fissures systematically in encapsulated solar cells was developed by junior scientist Dr. Martin Sander in a project funded by the German Federal Ministry of Education and Research as part of the excellence cluster competition "Solar Valley Middle Germany" at the Fraunhofer CSP. In his method, the solar cells in a module laminate are exposed to mechanical loads under defined boundary conditions. To this end, a universal test machine with a 4-point bending facility was combined with an electroluminescence camera (EL camera) and an automatic test procedure was programmed. The load was increased gradually in increments. An EL image was produced upon each load increase, so that the resulting fissures could be allocated exactly to the load that caused them. By drawing on results derived from a finite-element simulation, each fissure could be assigned to a breaking tension. This enabled the analysis of future module structures with novel solar cells, glasses or encapsulating materials under defined laboratory conditions and allows for the prediction of the probability of a fissure to occur under a given mechanical stress.

Fraunhofer Center for Silicon Photovoltaics CSP

Fraunhofer Center for Silicon Photovoltaics CSP