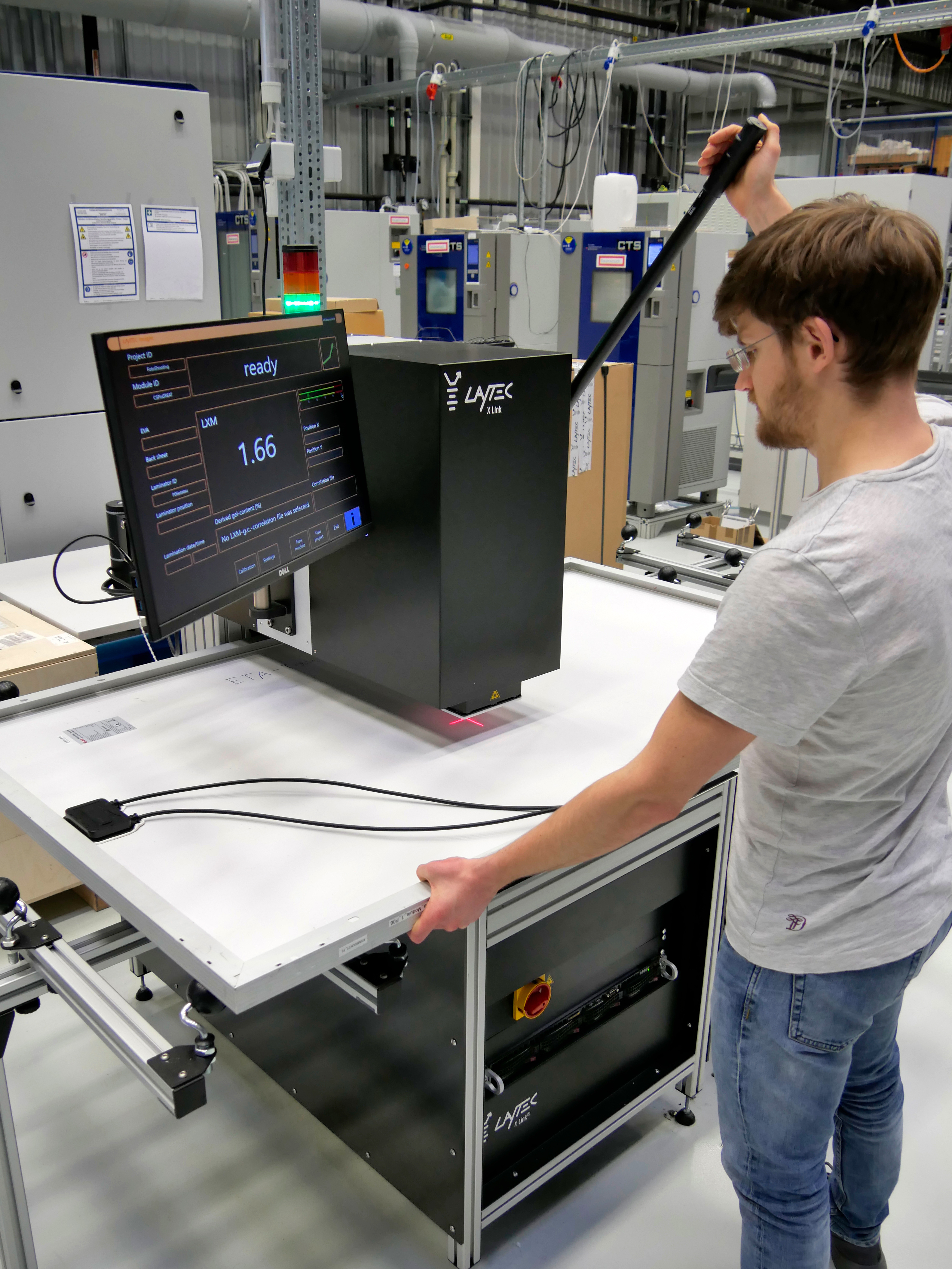

X-Link: Lamination Control

The X-Link testing device can be used to non-destructively identify material and process defects in the laminations of PV modules.

- Non-destructive lamination control of PV modules:

- Measurement of the degree of interconnection of encapsulation films: EVA, POE

- Calibration required for each new BOM (encapsulation and backsheet), creation of calibration series is also possible

- Suitable for glass-foil modules

- 2D mapping possible

- Identification of material or process defects

- Measurements on the minute time scale

Fraunhofer Center for Silicon Photovoltaics CSP

Fraunhofer Center for Silicon Photovoltaics CSP