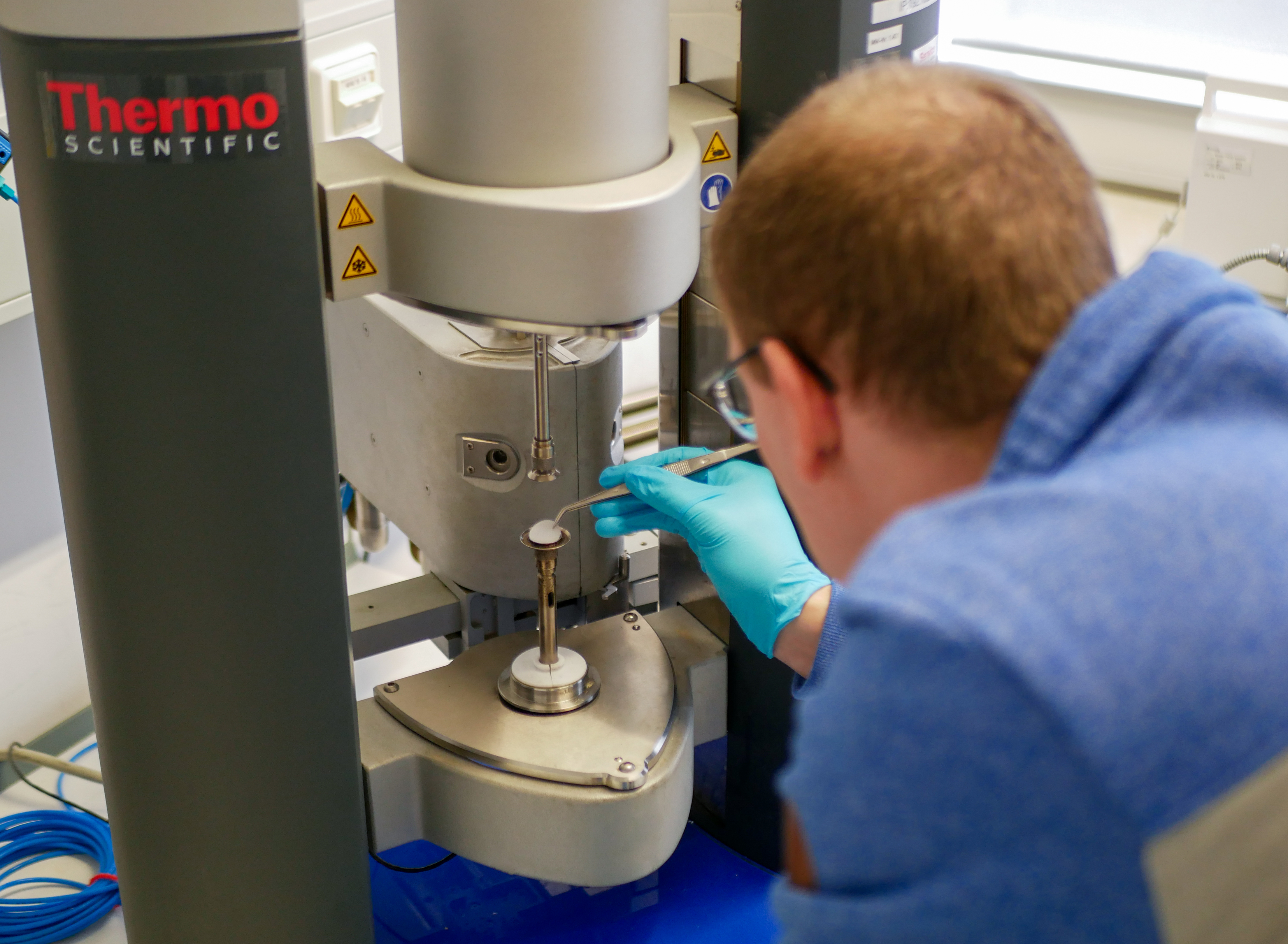

DMA: Dynamic Mechanical Analysis

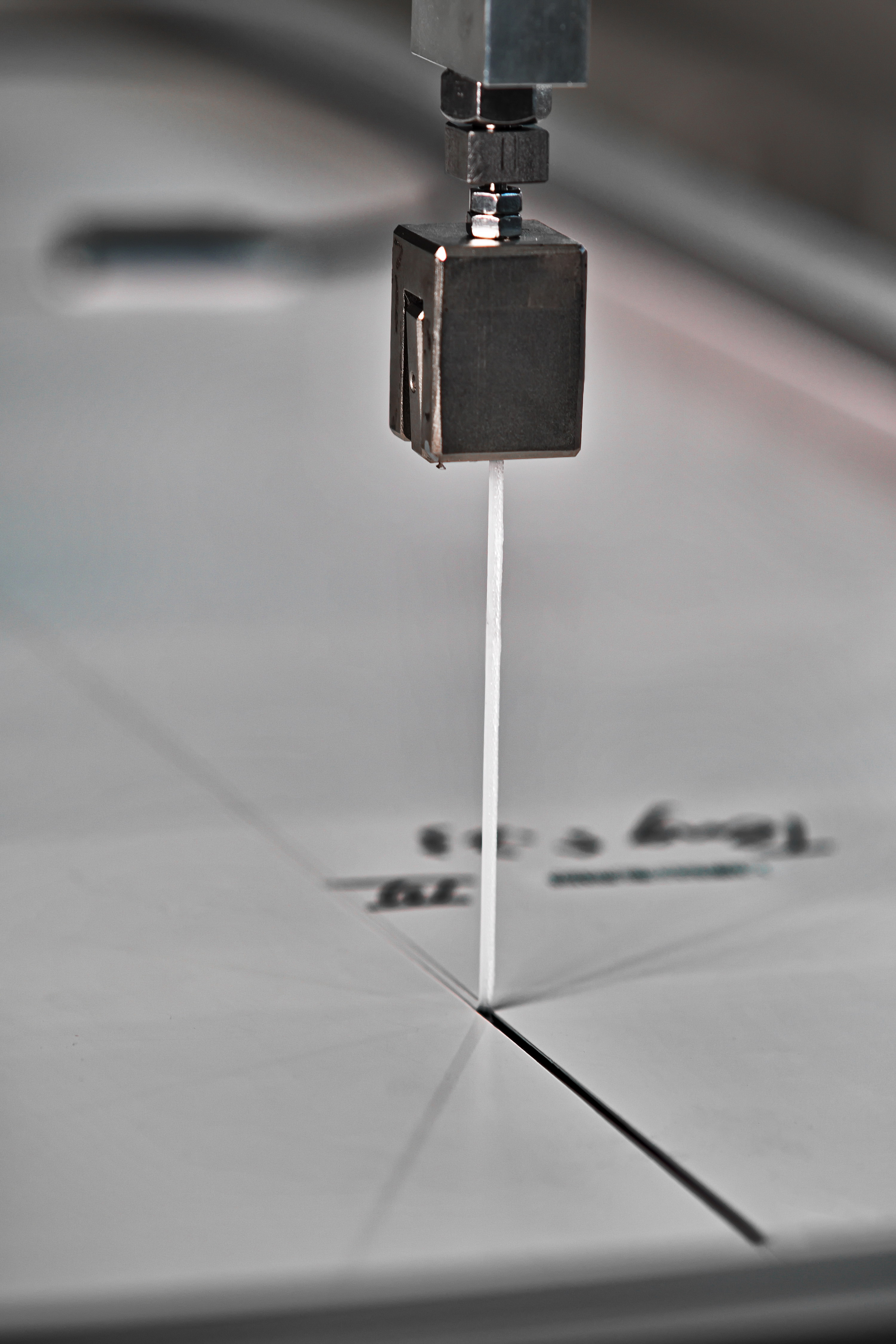

Dynamic Mechanical Analysis (DMA) determines the frequency-, amplitude-, and temperature-dependent mechanical properties of solids.

- Determination of frequency-, amplitude- and temperature-dependent mechanical properties of solids, T: -170°C to 600°C, f: 0.01 Hz to 100Hz

- glass transition temperature

- crosslinking density

- generation of master curves according to time-temperature superposition

- crosslinking kinetics

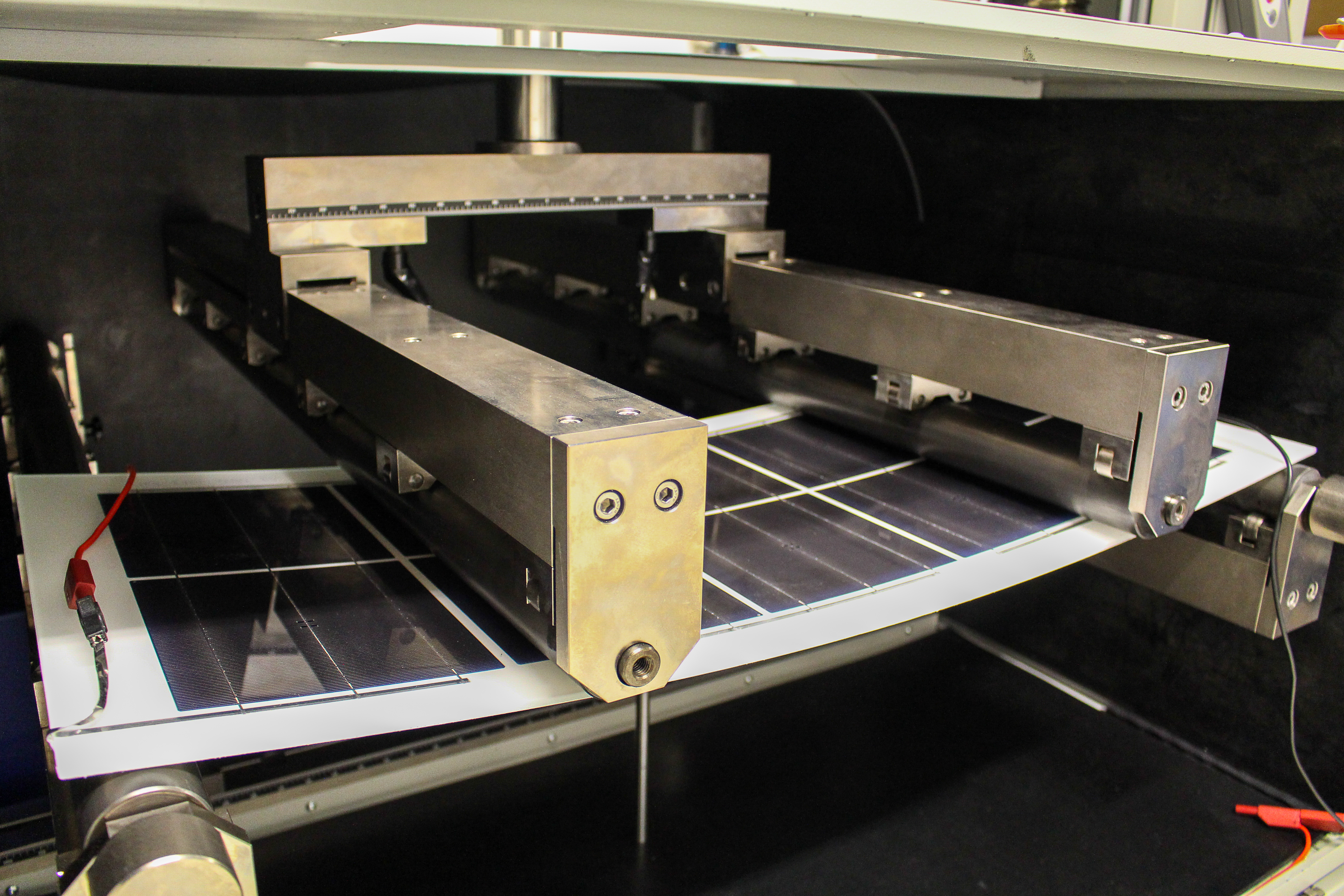

Fraunhofer Center for Silicon Photovoltaics CSP

Fraunhofer Center for Silicon Photovoltaics CSP