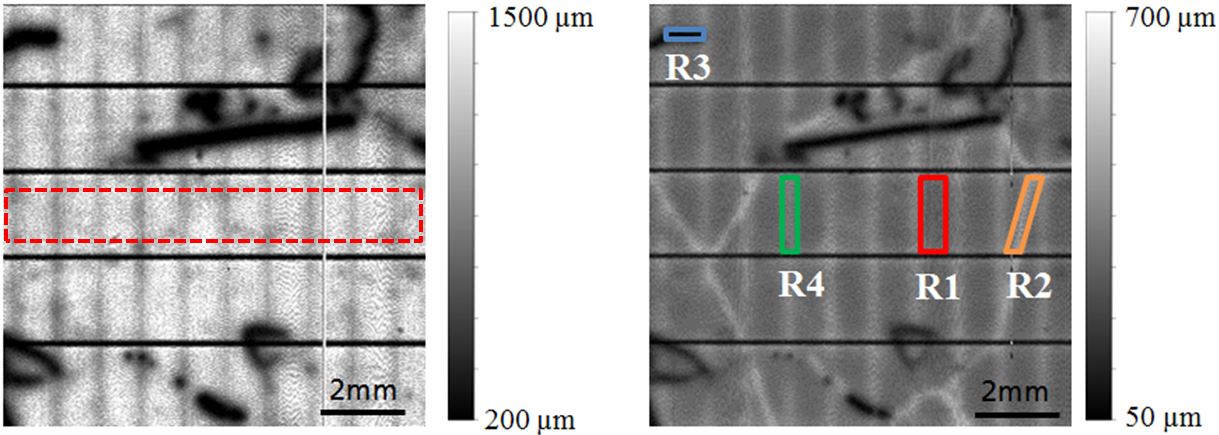

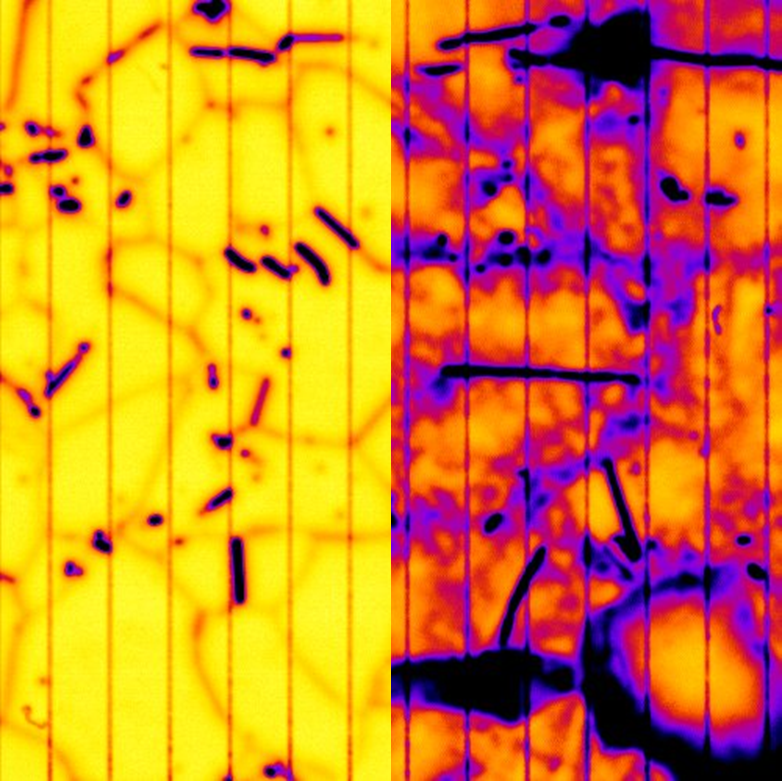

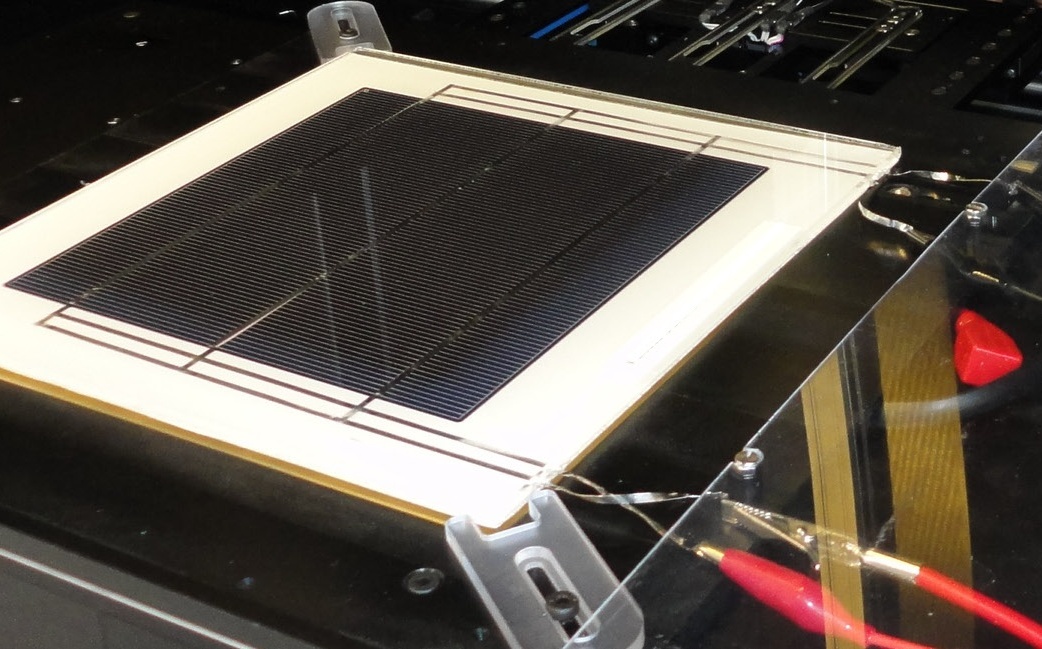

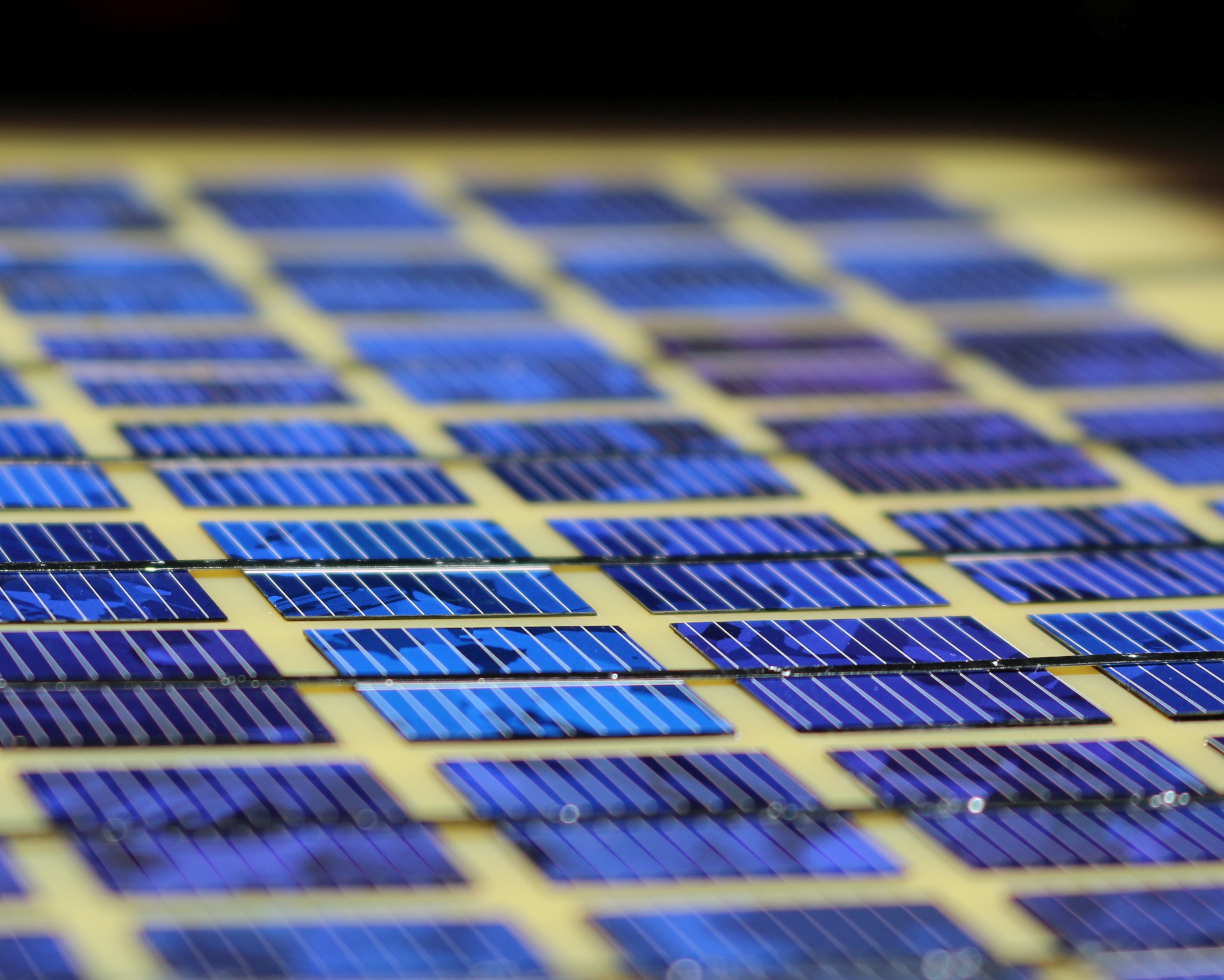

High efficiency and a long service life are two of the central demands placed on innovative photovoltaics products. Individual module components as well as complete modules must satisfy the highest standards. To obtain a quantitative evaluation, the Fraunhofer CSP applies innovative laboratory measurement methods applicable to solar cells and modules in combination with statistical data evaluation, model building and numeric simulation. In addition, a macroscopic assessment by means of spatially and spectrally resolved measurements is an essential element in our multiscale approach to identify the causes of defects, in which both macroscopic and microscopic fault patterns are associated with production-related performance parameters.

Fraunhofer Center for Silicon Photovoltaics CSP

Fraunhofer Center for Silicon Photovoltaics CSP