Reducing Inverter Failures and Malfunctions

Inverters are the essential key component for feeding the electrical energy generated by solar modules into the power grid. How can failures and malfunctions of these inverters be reduced? The Fraunhofer Institute for Microstructure of Materials and Systems IMWS is investigating this question in cooperation with DiSUN Deutsche Solarservice GmbH and DENKweit GmbH as part of the "robStROM" project funded by the German Federal Ministry for Economic Affairs and Climate Action.

In the course of the energy transition, the share of renewable energies as part of the electricity supply is to almost double in less than ten years. While it was still around 41% in 2021, it is expected to reach at least 80% by 2030. To achieve a swift and socially acceptable energy transformation in Germany, the costs of electricity generated from renewables must fall further. For the photovoltaic sector, this means that the operational capability and reliability of the plants must also be increased even further.

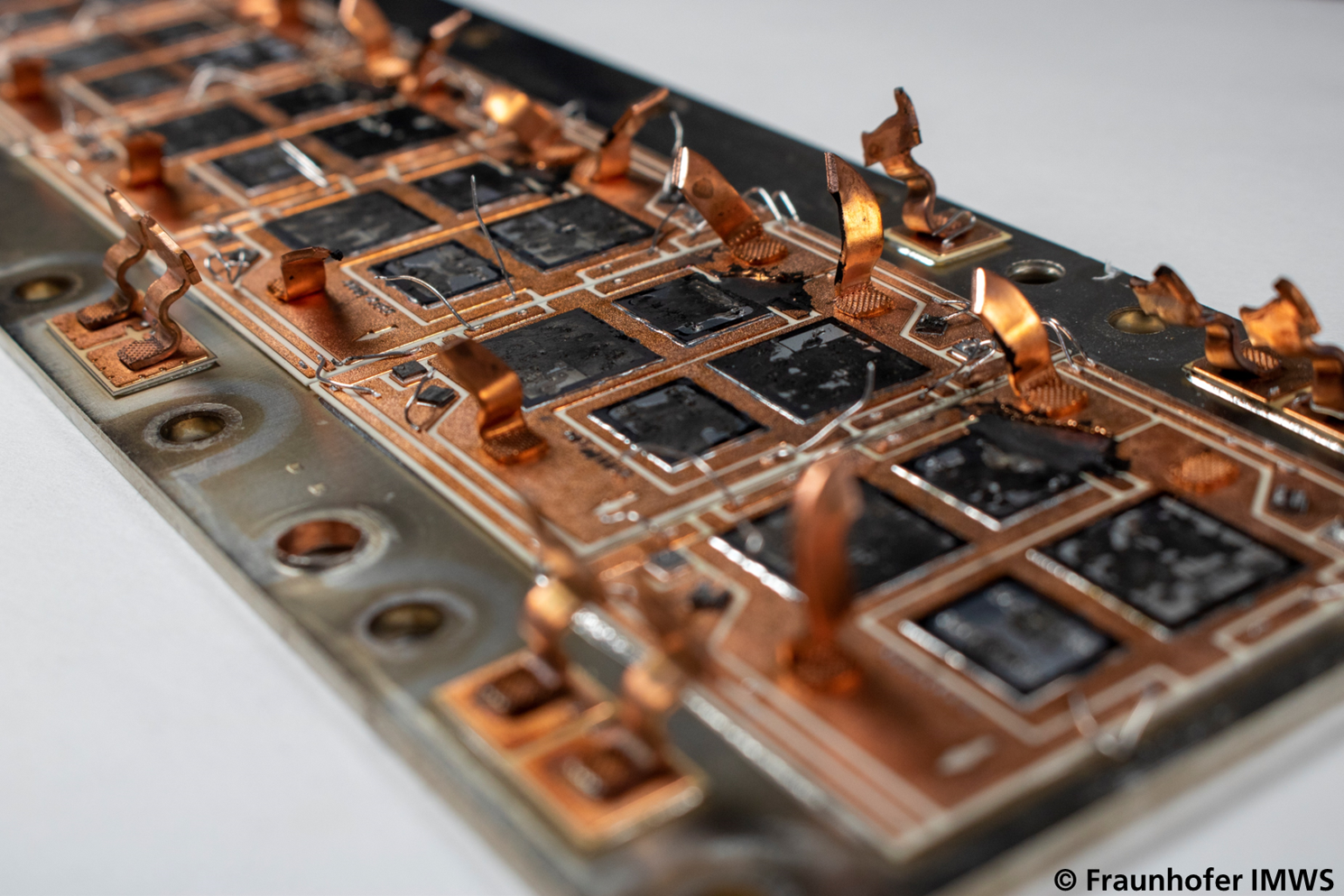

Inverters, which convert the direct current produced by solar modules into usable alternating current, play an essential role in this context as failures or malfunctions of inverters lead to a partial or complete shutdown of a PV system. As a result, the reliability of energy supplies cannot be assured, operators and investors incur financial losses and maintenance and operating costs will rise.

This is where the joint project "More Robust PV Systems and Operation Management by Analyzing Power Converter Failures" (robStROM) sets in. Together, Fraunhofer IMWS, DiSUN Deutsche Solarservice GmbH and DENKweit GmbH are developing effective data-, AI-, diagnostics- and analytics-based methods to reduce inverter failures. These methods will make it possible to avoid failures through root cause analysis and early detection and reduce the workload on operations management through maintenance schedules based on prior failure experience. Diagnostic and measurement results from basic research will provide information about the causes of failure mechanisms, and defect statistics based on monitoring data of a sizeable solar power plant portfolio will provide information about inverter failures. Cause and effect are thus combined.

"Fraunhofer IMWS brings its expertise from two areas to the project, which also cover the focus areas "cause" and "effect". On the one hand, the experience of the group "PV Systems and Integration", which deals with modern test methods for system diagnostics and AI-supported damage analysis and yield prediction of PV power plants and the optimization of energy systems; on the other hand, the experience of the group "Assessment of Electronic Systems Integration", which analyzes microstructures, material interactions or defect formations in correlation to technology, material selection and design as well as the operational conditions in detail and thus understands and improves the influence of manufacturing processes and reliability in application," says Dr. Matthias Ebert, group leader "PV Systems and Integration" at Fraunhofer IMWS.

PV system diagnostics is one of the main topics of this year's Fraunhofer IMWS trade show participation at Intersolar Europe, which will take place in Munich from June 14-16, 2023. Visit us at booth A2.209 and learn how AI and virtual reality can optimize operation and maintenance of PV systems in the future.

Fraunhofer Center for Silicon Photovoltaics CSP

Fraunhofer Center for Silicon Photovoltaics CSP