Background and Project Objective

Raesch specializes in the manufacture and development of high-quality quartz glass and specialty glass products. It offers solutions for applications that require the highest purity and special material properties, for example in the semiconductor industry, optics, research, and medical technology. Raesch places particular emphasis on quality, purity, and innovative technologies in order to meet the demanding requirements of its customers.

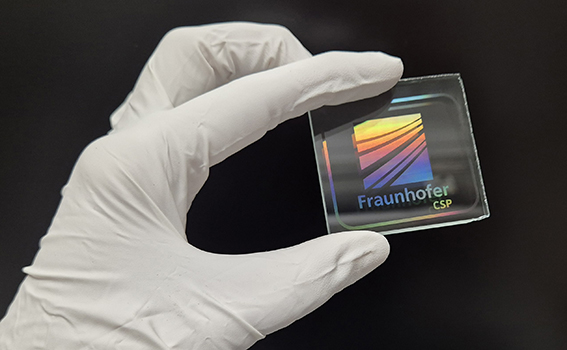

For the application of quartz glass in the semiconductor industry, a depth-dependent trace element analysis is required, in which the levels of contamination in specific areas and in the bulk material can be determined.

Innovation and Customer Benefits

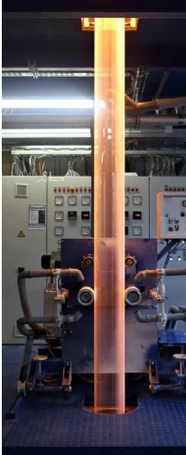

Fraunhofer CSP has carefully evaluated existing analysis methods from silicon analysis and adapted them specifically to the requirements of quartz glass. An innovative deep etching method consisting of three clearly defined steps was developed. After extensive etching experiments to determine the specific etching rate, samples can be etched precisely to a specified depth and then analyzed using high-precision ICP-MS (inductively coupled plasma mass spectrometry).

The next step is a bulk analysis, and the results are correlated with those of the near-surface etching steps. This allows us to determine exactly whether elements are evenly distributed in the quartz glass or have been introduced from outside by certain process steps. This leads to a better understanding of the manufacturing processes, higher material purity, and improved control of the process chain. This analysis is crucial for quality assurance and compliance with strict purity requirements, especially in applications where even the slightest traces of metals or contamination can negatively affect product quality.

Fraunhofer Center for Silicon Photovoltaics CSP

Fraunhofer Center for Silicon Photovoltaics CSP